Processes

Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

WatchColorado State professor earns NSF award for composites 3D printing

Mechanical engineering professor Mostafa Yourdkhani’s novel in-situ printing and curing techniques for composite materials, including carbon fiber, earned him the Faculty Early Career Development Award.

WatchIlium FLEXmat fiberglass is suitable for pultrusion processes

Latest long chopped glass fiber reinforcement technology enables high temperature exposure, material stretching and chemical resistance, making it a safer cleaner option for pultrusion manufacturing.

Read MoreAerospace project secures funds for developing lightweighting technology

A joint project between ÉireComposites, Plasma Bound and TU Dublin will be supported by the DTIF.

Read MoreRoboze 3D printing partners with Yamaha Motor Racing

Yamaha Motor Racing selects Roboze as its technology partner for high-performance 3D printing with super polymers and composite materials.

Read MoreAirborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

Read MoreBlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

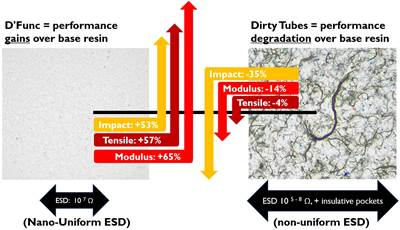

Read MoreMechnano trademarks CNT dispersion process for AM materials

D’Func dispersions eliminate clumped and roped CNTs, leading to increased electrical and mechanical performance in 3D-printed parts.

Read MoreXlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MoreOrbital Composites licenses AMCM technology

Additive manufacturing compression molding (AMCM), co-developed with ORNL, combines robotic AM and continuous fiber technologies to revolutionize high-volume composites manufacturing.

Read More