XlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

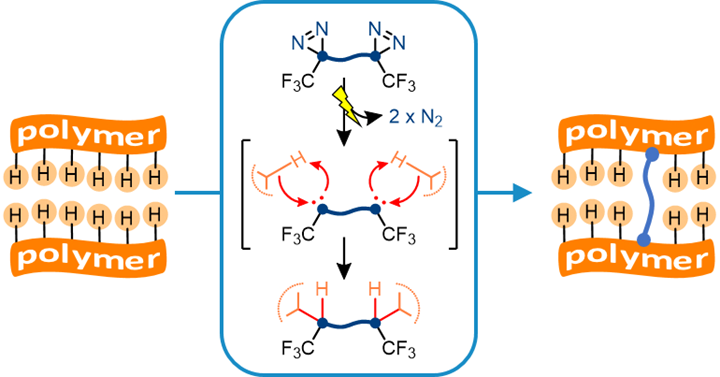

XlynX compound cross-linking process. Photo Credit, all images: XlynX

(Victoria, Canada) has received a 2023 Innovation Award from the Adhesion and Sealants Council (ASC) for “Development of Universal Covalent Adhesives for Use with Low Surface Energy Polymers” (see “XlynX Materials releases new polymer molecular glue: BondLynx).

Low surface energy (LSE) polymers such as polyethylene (PE) and polypropylene (PP) are materials that are increasingly found at the forefront of technological innovation, from ropes and mechanical parts to performance textiles and medical devices. According to XlynX Materials, this is because LSE polymers are relatively cheap to produce, can be molded to specific dimensions and offer high strength, durability and resistance for such lightweight materials. However, these same qualities result in LSE polymers that are resistant to adhesion (gluing), layering, coating and dyeing applications, which limits how they are used.

In response to this challenge, XlynX Materials has developed a highly reactive suite of compounds that chemically insert themselves into unreactive polymer surfaces. In this way, they are reported to transform LSE polymers into materials that are no longer resistant to gluing, coating or other adhesion-based applications. This breakthrough “diazirine” technology enables abundant polymers to be used in a host of new applications.

According to Dr. Jeremy Wuff, lead inventor and scientific advisor for XlynX Materials, “We were first to develop a cross-linking molecular adhesive for this kind of use with commodity polymers, and we aim to remain a leader in this innovative field of diazirine chemistry.”

XlynX’s senior research scientist, Dr. Stefania Musolino receiving Innovation Award from Adhesion and Sealants Council (ASC) in New Orleans, Louisiana.

The new compounds, known as BondLynx and PlastiLynx, are easy to apply and are activated by either moderate heat or UV/Vis light. They are primarily designed as adhesives, primers and textile strengtheners. According to lap shear tests, the strength of bonds between LSE polymers — glued together with traditional, store-bought adhesives — have been increased by as much as 950% when first primed with XlynX’s compounds. Moreover, the company’s products have shown potential in new applications like organic electronics stabilization, quantum dot photopatterning and new composite material development.

Product samples for testing and research purposes are available. Please send requests to info@xlynxmaterials.com to consult with XlynX experts.

Related Content

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.