Prepregs

Under the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

Read MorePerformance requirements: CAI vs. OHC

John Russell, who manages nonautoclave research programs for the Air Force Research Laboratory (AFRL, Wright-Patterson AFB, Ohio), recently threw down the gauntlet at the Fall SAMPE conference in Salt Lake City, Utah: “Give us a 25 percent improvement in notch properties with no microcracking in high-modulus fibers.” While OOA prepreg suppliers can’t do much about fiber microcracking, Advanced Composites Group (ACG, Tulsa, Okla.) already has announced that its XMTM47 material will be commercial by next year, designed for 120°C/248°F service with the increased notched performance requested.

Read MoreOut-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

Read MoreGKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

Read MoreDrag racing champ wins with composite rear wing

A composite rear wing assembly built by Aerodine Composites Group (Indianapolis, Ind.) was critical to 2010 NHRA Full Throttle Drag Racing Series champion Larry Dixon’s effort at the wheel of the Al-Anabi Top Fuel dragster.

Read MoreCFRP upgrades economy seating

First aircraft seat to use visible CFRP revolutionizes aesthetics and comfort.

Read MoreFuel cells (finally) set to power composites growth

Fuel cells and related technologies will form a sizable new market as they move past the phase of demonstration projects, overcome longstanding technology hurdles and gain momentum in their progress toward affordability.

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

Read MoreThe Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

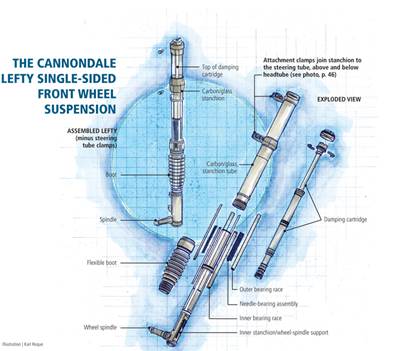

Read MoreIn search of a better ride

Composites minimize weight on this mountain bike’s unconventional, single-sided front-wheel suspension system.

Read More