Prepregs

Unweighting a crane to increase payload limit

Rethinking a crane stinger with carbon fiber for a more “uplifting experience.”

Read MoreThinking outside the prepreg box in aerospace

A challenge to “outside the box” thinking about prepreg.

Read MoreHarbin Hafei Airbus partners with Plataine and Argosy for improved traceability, efficiency and yield

Joint venture composites manufacturing center implements Plataine solution for tracking parts, materials and tools.

Read MoreAutomated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

WatchPreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

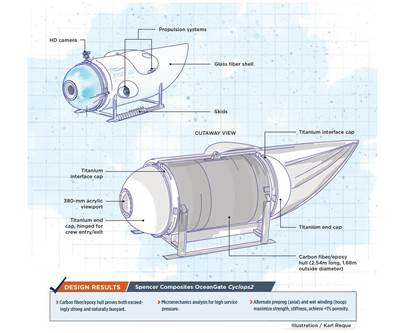

WatchComposite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

Read MoreThe automotive industry’s “killer app”?

Automotive is king, and the killer automotive app will be the multi-material and all-carbon-fiber B-pillar.

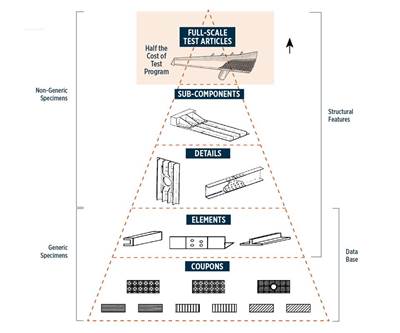

Read MoreAccelerating materials insertion: Where do virtual allowables fit?

In the quest to reduce the time and cost for aerocomposite design allowables development, will conventional physical testing and virtual testing go head-to-head or work side-by-side?

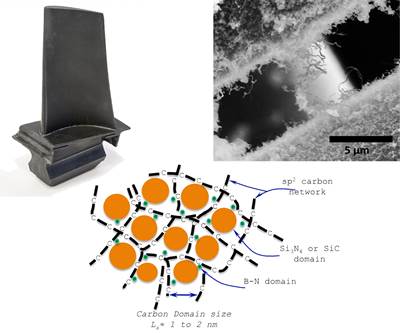

Read MoreCommercialization of CMCs and developments for next-gen performance

As industrial production of parts begins, new developments offer promise for higher-temperature and more damage-tolerant ceramic matrix composite (CMCs).

Read MoreHybrid carbon fiber/aluminum suspension knuckle

Yields 26% greater stiffness via bonded prepreg patch.

Read More