Prepregs

TenCate's acquisition of Amber Composites a sensible surprise

TenCate, known for years as a thermoplastics specialist, is signaling more and more that it wants to move into new markets with new materials.

Read MoreAutomotive SMC: The wheel comes full circle

James Canner (Sterling Engineering & Mfg., Royal Oak, Mich.) explains why it is, once again, an exciting time to be a part of the automotive composites industry.

Read MoreFormulation flexibility: Direct-SMC

Consortium applies inline-compounding technology to reinvent sheet molding compound.

Read MoreSpare wheel well: Functional integration

Gas-assist injection molding enables one-piece, one-shot thermoplastic composite/metal hybrid.

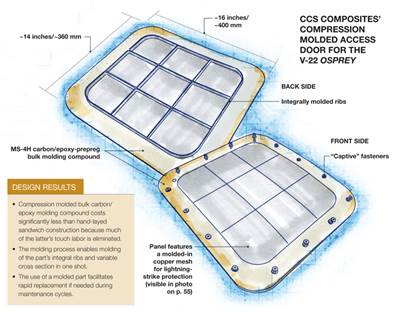

Read MoreSMC sandwich panels: Lean process opens doors

Patented process enables compression molding at lower pressures, saving capital equipment costs for panel fabrication.

Read MoreRedesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

Read MoreAirbus A350 Update: BRaF & FPP

EADS Innovation Works pursues qualification of Braided Frames for the A350-1000 fuselage and develops Fiber Patch Preforming for complex local reinforcements.

Read More2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

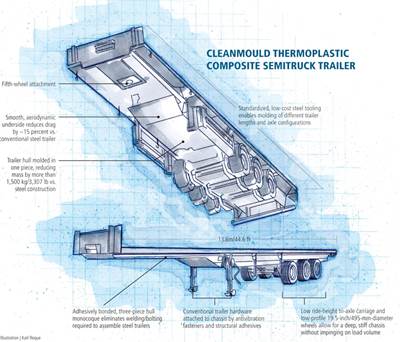

Read MoreThermoplastic composites: Sustainable transport

Cyclic PBT oligomers used to mold Class 8 semitrailer bed via vacuum-bag processing.

Read MoreTPCs on the Boeing 787 and Airbus A350

Although The Boeing Co.’s (Seattle, Wash.) 787 Dreamliner and the Airbus (Toulouse, France) A350 XWB have earned much press as showcases for thermoset composites in aircraft structure, both programs also have advanced the use of thermoplastic composites.

Read More