Out of Autoclave

Fully U.S.-made fairing launched into space features OOA composites

A United Launch Alliance Atlas V rocket launched a U.S. defense satellite into space. The payload fairing, produced by RUAG Space, is composed of OOA CFRP face sheets.

Read MoreHigher performance, lower cost helicopter rotor blades developed with OOA, FAA-qualified composites

Erickson Inc. and partner Toray Advanced Composites replaced legacy aluminum S-64 main rotor blades with out-of-autoclave, multi-material composite alternatives.

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

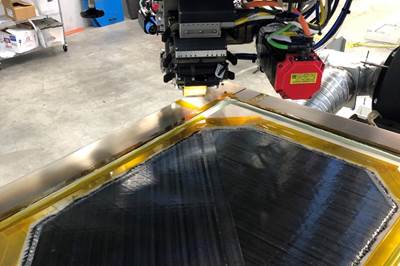

Read MoreElectroimpact, Toray, Janicki advance technologies for rapid, large-scale thermoplastic parts manufacture

Project combines Electroimpact high-speed AFP equipment, Janicki’s OOA heated layup tooling system and Toray Cetex TC1225 low melt PAEK UD tape for deposition rates of up to 4,000 inches/minute.

Read MoreSpirit AeroSystems Europe delivers first set of A320 Family RTM spoilers

Redesigned spoilers developed via a highly automated advanced manufacturing, out-of-autoclave (OOA) process pioneered by Spirit.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

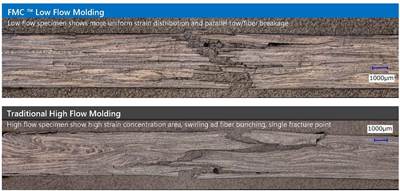

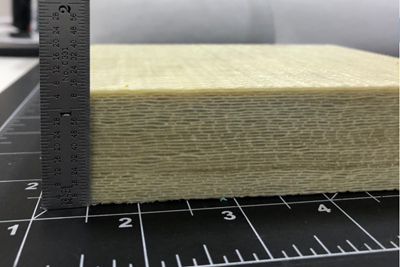

Read MoreForged molding compound: Extending SMC capabilities

New material, design, process combination approaches prepreg performance with chopped carbon fiber SMC.

Read MoreNew thermoset matrix resin offers fast, low-temp, tunable cure

HARP Rapid is a new thermoset resin chemistry for liquid molding processes that offers a fast, tunable cure profile, and a Tg that exceeds the material’s cure temperature.

Read MoreBraided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

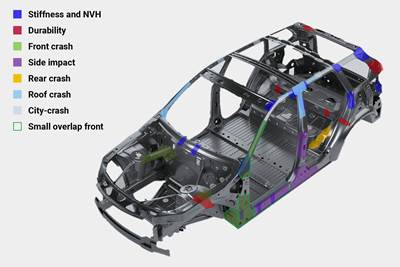

WatchComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

Read More