Out of Autoclave

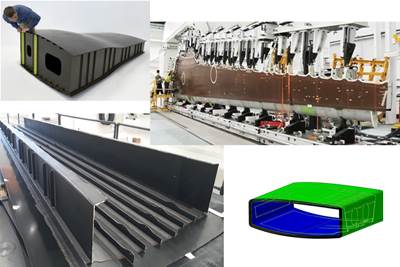

Advancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

Read MoreThe path to OOA wings with minimal fasteners

A review of the quest to eliminate both the autoclave and mechanical fasteners in composite wing structures.

WatchHot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

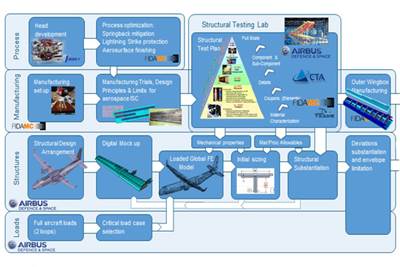

Read MoreIIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

Read MoreHexPly XF surface materials satisfy high-quality wind blade surface finish

Suitable for prepreg and infusion processes, Hexcel’s HexPly XF reduce shell manufacturing time by up to 2 hours and removes all surface defects prior to painting.

Read MoreVolansi VTOL drone delivery leader and composite manufacturer Quickstep sign MoU

The two companies will promote Volansi drones to commercial, defense markets and discuss Quickstep’s proprietary AeroQure process for drone production.

Read MoreHawthorn Composites awarded structural inlet duct manufacturing contract

Manufacture of inlet ducts for Kratos unmanned combat aerial vehicle involves an automated dry fiber overbraiding process, VARTM infusion and oven cure.

Read MoreSolvay, Leonardo launch joint research lab for thermoplastic composites

The Solvay Leonardo Joint Research Lab aims to facilitate the broader adoption of thermoplastic composites by the aerospace industry.

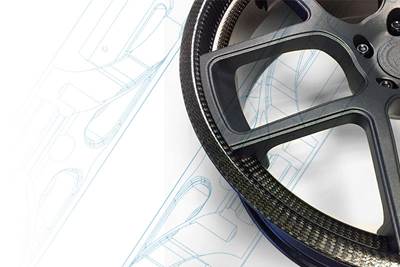

Read MoreCarbon ThreeSixty, Leonardo, NCC all-composite helicopter wheel project takes off

The 18-month project will design, develop and manufacture 12 fully tested ultra-low mass, robust, proof-of-concept CFRP wheels for rotary wing aircraft.

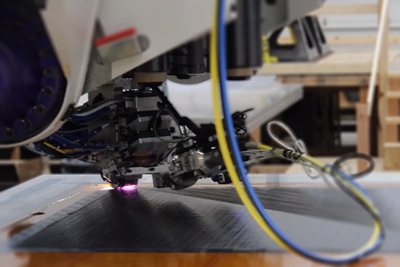

Read MoreVictrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

Read More