Out of Autoclave

Episode 36: Dale Brosius and Uday Vaidya, IACMI

IACMI’s Dale Brosius and Uday Vaidya talk about the first five years of the organization, how it has evolved and what the future might hold as IACMI continues its quest to help drive composite materials and process growth.

ListenSpintech opens new composites manufacturing division, Hawthorn Composites

New division specializes in manufacturing complex geometry composite parts using novel dry fiber preforming and resin infusion techniques, extending Spintech composite capabilities.

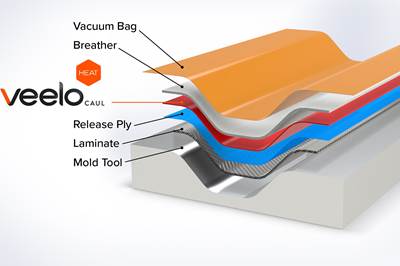

Read MoreVeeloHEAT Caul enables in-situ hot debulking capabilities

Built on existing debulk bagging procedures, Veelo Technologies’ debulking solution can take place at the tool during layup, reducing costs and improving throughput.

Read MoreDieffenbacher D-LFT line offers increased application, throughput flexibility

Efficiency, flexibility and increased performance are enabled by larger extruder pairs specially designed for the use of different thermoplastic materials.

Read MoreMultilayer thermoplastic tapes, AFP and resin infusion for more democratic composites

Novotech advances new materials and more affordable automated processes for small aircraft and beyond

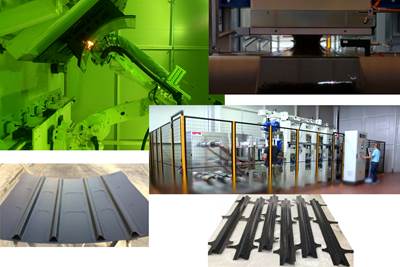

WatchCarbon fiber automotive parts production industrialized via C-RTM process

Compression resin transfer molding overcame the difficulty in shaping CFRP car parts with development time reduced by 50%.

Read MoreSHD, Piran contribute advanced composite capabilities to UAV platforms

SHD Composites has supplied advanced composite materials, and tooling, and Piran its manufacturing capabilities, for projects developed by Prismatic Ltd. and BAE Systems.

Read MoreVeelo Technologies' composite repair blankets reduce F-35 program costs

VeeloHEAT Cauls and VeeloHEAT composite repair blankets provide uniform heating, even on complex geometries, and will eliminate the need to move tooling to an autoclave for debulking.

Read MoreMoving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

Read MoreEpisode 34: Carmelo Lo Faro, Solvay Composite Materials

Carmelo Lo Faro, president of Solvay Composite Materials, talks about how he sees aerocomposites evolving in the time of COVID-19, the rise of computational power to evolve composites use, the prospects for increased composites use in the automotive market, and the increasing importance of education in the composites industry.

Listen