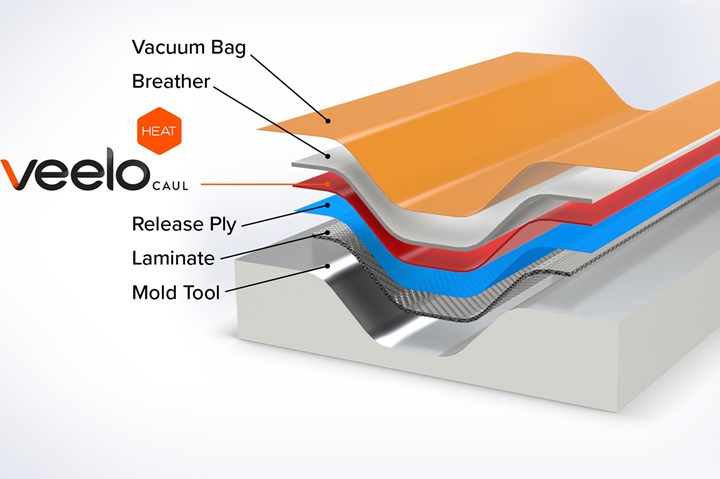

VeeloHEAT Caul enables in-situ hot debulking capabilities

Built on existing debulk bagging procedures, Veelo Technologies’ debulking solution can take place at the tool during layup, reducing costs and improving throughput.

Photo Credit: Veelo Technologies

Veelo Technologies (Cincinnati, Ohio, U.S.) leverages its heat technology capabilities to help manufacturers stay out of the autoclave and oven by offering a complete composites debulking system, the . A lightweight heating solution that builds on existing debulk bagging procedures, the system enables effective and reliable in-situ hot debulk, eliminating the need to transport parts to an autoclave or oven. Debulking can take place at the tool during layup, substantially improving throughput and build rates, thus reducing overall manufacturing costs.

Due to its flexible and pliable design, the durable and damage-resistant caul is highly uniform across large surface areas and can easily accommodate custom shapes and large tools. It features an FKM-based heater system for high performance and material compatibility. In addition to fatigue resistance, and a temperature range between 100ºF-400ºF, the system is also electrically efficient, with faster heating and cooling capabilities.

The caul is also controlled by the , a cost-effective solution capable of controlling up to 16 zones or more. The digital IoT controller is capable of storing data and receiving updates locally or via the cloud and is highly customizable.

Applications may include out-of-oven heated debulk, out-of-autoclave composite processing, accelerated cure in autoclave processing, net-shaped composite repair, secondarily-bonded heater for metallic tooling and secondarily-bonded heater for electrothermal de-icing.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.