Infusion

Saab Aerostructures announces composite cargo door iteration, flaperon developments

Saab Aerostructures has reported updates to two of its composites-related projects, an RTM’d flaperon and the next iteration of the Clean Sky 2 technology demonstrator cargo doors.

Read MoreCustomized resin flow mesh products save time, cost for wind turbine blade manufacturers

As longer composite wind blades are developed, customized mesh products help OEMs and kitting companies control resin flow and remove air voids during infusion.

Read MoreIrkut completes final assembly of composite-intensive MS-21-300 aircraft

The MS-21-300 design is approximately 40% composite, which Irkut says is a record figure for medium-range aircraft. After switching to local production, the first aircraft is about to fly.

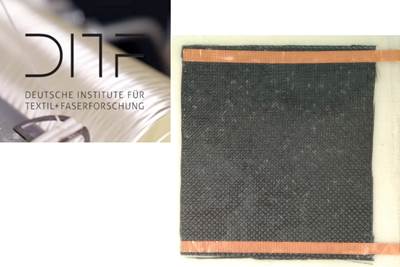

Read MoreDITF develops textile sensors for composites

German Institutes of Textile and Fiber Research are advancing large-area sensors that can detect deformations and stress using printing onto textiles which are then incorporated into composite structures.

Read MoreAll-electric motor boat tests the waters for recycled carbon fiber

RS Sailing aimed to create a fully electric, rigid inflatable boat (RIB) that is produced as sustainably as possible. A few iterations later, the Pulse 63 is ready to hit the water.

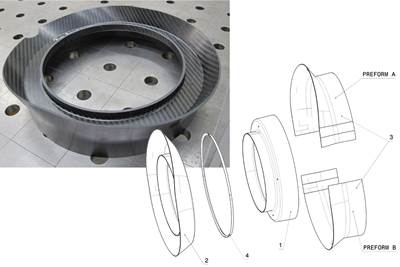

Read MoreComposite ring frame improves safety, cost for workhorse helicopter

Airbus Helicopters replaces aluminum primary structure with CFRP using multi-piece preform and single-shot infusion.

Read MoreClean Sky 2 FUSINBUL project develops full-scale, carbon fiber pressure bulkheads

Two 3.5-meter pressure bulkhead demonstrators incorporate advanced layup techniques with the goal of increasing serial production capabilities for fuselage manufacture for regional aircraft.

WatchBrazil-based Gatron manufactures fiberglass composite deflectors for concept truck

Five deflectors in total combine a sinuous, aerodynamic design, high strength and low weight.

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

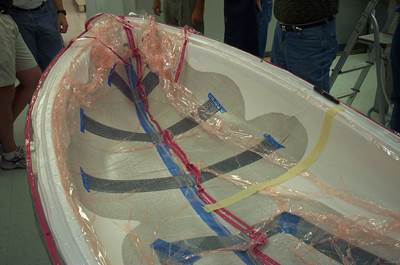

Read MoreTech Table: Vacuum bagging supplies

This is the fifth in a series of Tech Tables and comprises vacuum bagging material data provided by suppliers.

Read More