Brazil-based Gatron manufactures fiberglass composite deflectors for concept truck

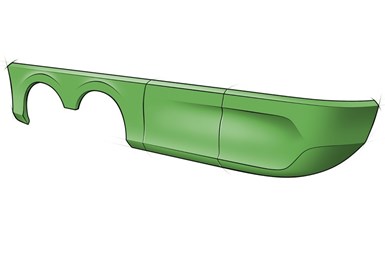

Five deflectors in total combine a sinuous, aerodynamic design, high strength and low weight.

Photo Credit, all images: Gatron

(Paraná, Brazil), a Latin American company that specializes in composite materials, has manufactured and installed the two side and three rear deflectors of the Efficiency Concept Truck (shown above), a concept vehicle created by Volvo.

The concept vehicle, says Gatron, serves as a platform for anticipating new technologies, including that of a tipper wheel road train which is reported to be a ton lighter than conventional ones developed by Randon Implementos (Brazil).

“Our engineering team worked closely with the Randon team to achieve the best result in terms of aerodynamic design and deflector weight,” says Camila Scarmin, commercial manager at Gatron. Manufactured via infusion, the deflectors are 1.8 meters (sides) and 2.4 meters (rears) in length.

Composite side deflector design.

“Infusion enabled molding with a high content of fiberglass. That is, we were able to produce light and very resistant components. In addition, we faithfully kept the design lines of the piece, which made all the difference in the final project,” emphasizes Scarmin.

One of the main challenges of this project was the production of molds that exactly reproduced the deflectors’ sinuous design.

“The fact that we have a 100% vertical operation was crucial for us to be successful in transforming designs into ready-to-install parts on the truck,” Scarmin concludes.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.