Infusion

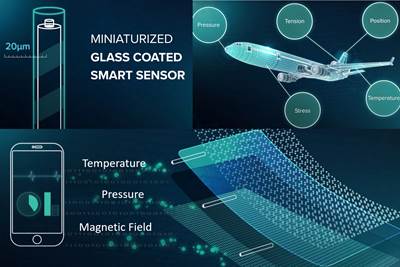

Contactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

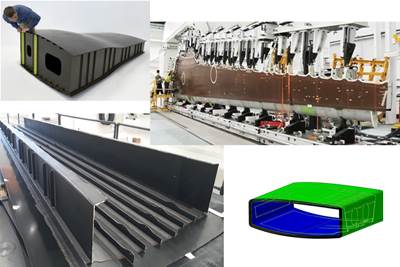

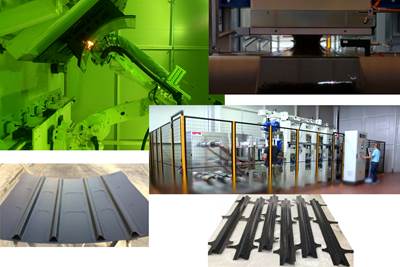

WatchAdvancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

Read MoreThe path to OOA wings with minimal fasteners

A review of the quest to eliminate both the autoclave and mechanical fasteners in composite wing structures.

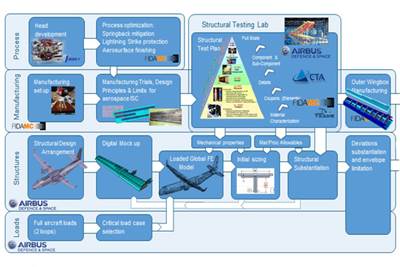

WatchIIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

Read MoreHexPly XF surface materials satisfy high-quality wind blade surface finish

Suitable for prepreg and infusion processes, Hexcel’s HexPly XF reduce shell manufacturing time by up to 2 hours and removes all surface defects prior to painting.

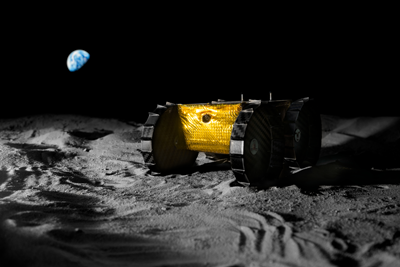

Read MoreComposites design helps nano-sized lunar rover hit big milestones

Developed by Carnegie Mellon University, the ultralight, composites-intensive Iris nano-rover will make its lunar debut later this year.

Read MoreMultilayer thermoplastic tapes, AFP and resin infusion for more democratic composites

Novotech advances new materials and more affordable automated processes for small aircraft and beyond

WatchComposites meet precision, weight goals for complex facade design

Brazilian fabricator Gatron manufactured 3,000 square meters of curved composite frames to support a 33-floor residential building.

Read MoreNext-generation composites materials and processes explored

A supplement with the November 2020 issue of ÂÌñÏ×ÆÞ takes a close look at some of the technologies that are driving innovation in the composites industry.

Read MoreOli46 Resin Blocker maintains infusion vacuum level

Technical flange is designed to avoid resin waste up to 80%, improve surface finish and save on cost and production time.

Watch