Infusion

Bally Ribbon Mills technology features infusion for 3D woven joints

Woven fabrics manufacturer Bally Ribbon Mills is highlighting its film infusion capabilities for 3D woven joints woven thermal protection systems and more.

Read MoreOrenco and FiberCore sign license agreement for InfraCore technology in U.S.

Collaboration matches delamination-resistant technology with large FRP structures expertise for new applications and U.S. market growth.

Read MoreJEC announces finalists for 2020 Innovation Awards

JEC Group has announced its JEC Innovation Awards finalists, 33 total from 11 categories. Winners will be announced at JEC World 2020 on March 4.

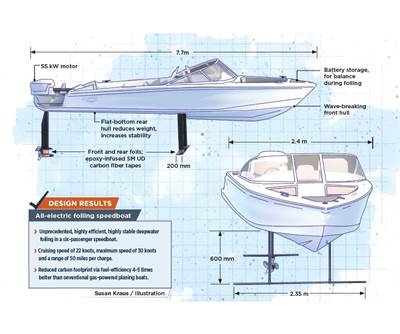

Read MoreComposites enable novel flying speedboat

Candela Boats’ Seven speedboat combines all-electric propulsion with precision foiling in a design made possible by creative composites engineering.

Read MoreThe coming decade: Clarity with a strong dose of uncertainty

Columnist Dale Brosius considers the potential and uncertain role of composites in aerospace, automotive and other markets in the coming decade.

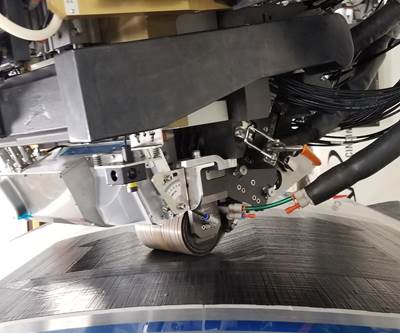

Read MoreDiving deeper into composite processes

CW recently had the opportunity to visit Abaris Training (Reno, Nev., U.S.), a company that has offered advanced composite training courses for more than 30 years.

Read MorePlant Tour: Holland Composites, Lelystad, Netherlands

Balancing performance with affordable production, this industry veteran continues to explore composites’ infinite possibilities.

Read MoreIACMI: Driving innovation in the advanced composites industry

Since its start in 2015, the Institute for Advanced Composites Manufacturing Innovation (IACMI) has come a long way in its mission of advancing composites innovation. CTO Uday Vaidya reflects on the past five years.

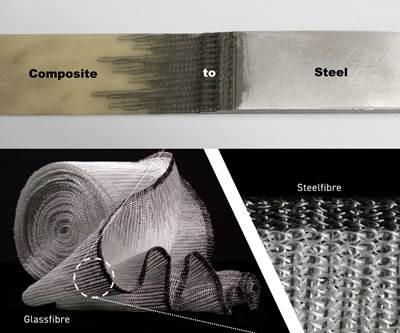

Read MoreConnecting composites to steel

Hyconnect combines glass and steel fibers with welding to lightweight structures.

Read MoreRemoving barriers to lightweighting ships with composites

EU consortia propel large demonstrators, new technology and affordable certification.

Read More