Fives/NRC in-process inspection platform. Source, all images | JEC Group

JEC Group (Paris, France) has announced the finalists for its annual JEC Innovation Awards. After pre-selecting 33 finalists, the jury now has one month to select a winner in each of 11 categories. The winners will be honored at an awards ceremony to take place during JEC World 2020 on Wednesday, March 4, at 5 p.m., on the Agora stage (Hall 5).

The international jury represents the entire composites value chain:

- Anurag Bansal, Manager Global Business development, ACCIONA Construction S.A.

- Christophe Binetruy, General Chairman & Professor, EC Nantes

- Robert Buchinger, Business Development Advanced Industry Systems, Swarco

- Chantal Fualdes, Head of Airframe Certification, Executive Expert Composite Airframes, Airbus

- Karl-Heinz Fuller, Manager hybrid materials, concepts and AMG, Daimler

- Sung Ha, Professor, Department of Mechanical Engineering, Hanyang University

- Deniz Korkmaz, Ph.D. Composite Technologies Director, EMEA, Kordsa

- Brian Krull, Global Director of Innovation, Magna Exteriors

- Yann Penfornis, Managing Director, Multiplast

- Henry Shin, Director - R&D Composites Innovation Centre, KCTech

- Kiyoshi Uzawa, Professor/ Director (Ph.D.), Innovative Composite Centre

An online voting process will be held for each category to choose a second-place winner for the general public’s favorite innovations. Beginning Feb. 1, the public will be able to vote online at .

Finalists for each category are listed below:

Category I. Additive Manufacturing

Part produced using Eurecat CFIP technology

Scalable Composite Robotic Additive Manufacturing — Electroimpact (U.S.)

SCRAM is an industrial true 6-axis continuous fiber reinforced thermoplastic 3D printing system, enabling the tool-less rapid creation of aerospace grade integrated composite structures.

CFIP Technology — Eurecat (Spain)

CFIP is a new post-process technology which enables to reinforce with continuous fibers parts made of any material and by any manufacturing technology.

Rapid 3D Microwave Printing of Lattice Composites — Karlsruhe Institute of Technology (Germany)

Developed the world’s first prototype of an ultra-high speed 3D microwave printer SERPENS. The bionic and free-standing lattice composite structures are printed by the SERPENS.

Category II. Aeronautics

Demonstration of Institut de Soudure Groupe’s solution for welding of thermoplastic composites

Innovative solutions for welding of TP composites — Institut de Soudure Groupe (France)

ISW is a new solution developed and patented by Institut de Soudure Group and ARKEMA, providing very high performance welding for thermoplastic composites

High-Rate Manufacture of Aerospace Composite parts — Solvay (U.K.)

A new material and associated process increasing the manufacturing rate of small to medium parts by 10-20 times while maintaining aerospace performance and quality and reducing the final part cost.

Intelligent Resin Infusion System (IRIS) Demo — Spirit AeroSystems (U.S.)

Fabrication process for composite aerostructures combining self- heated tooling, resin infusion, and advanced automation to reduce equipment and materials cost and improve rate and design integration.

Category III. Automotive

Structural hybrid thermoplastic automotive body component from Volkswagen AG

Pultrusion for popularization of CFRP Body Parts — Hyundai Motor Group (South Korea)

This innovation sheds light on challenges of for mass production automotive application with a new pultrusion process.

Overmolded organosheet bolster — Valeo (France)

An overmolded organosheet bolster designed for mass production (300000 parts/year), compliant with aesthetic aspect requirement, mechanical properties and recyclability.

Lightweight FRP center tunnel (LehoMit-Hybrid) — Volkswagen AG (Germany)

Innovative cost-efficient structural hybrid thermoplastic automotive body component suitable for high volume production, introducible prior to cathodic dip coating with respective joining technology.

Category IV. Construction, Infrastructure and Civil Engineering

CL RESTRAP — CARBO-LINK AG (Switzerland)

Thin, cured CFRP prepreg tapes continuously wound in a loop to form a flexible carbon strap. Highly customized solution to reinforce concrete girders of any size in any infrastructure lasting forever.

GlasCurtain ThermPH+ — GlasCurtain inc. (Canada)

Leveraging Thermoset Polyester Fibreglass-Reinforced Plastic (TP- FRP), GlasCurtain has designed and engineered the highest thermally performing curtain wall system in the world: ThermPH+.

APP/APN: Hybrid Thermal Insulation Sheet — Hankuk Carbon (South Korea)

Semi-non-combustible thermal insulation, dimensional stability, anti- oxidation treatment.

Category V. Design and Furniture

Mecelec flax fiber BMC dome roof

Gladiator Hybrid Composite Beverage Carrier — AB InBev (Belgium)

Gladiator Hybrid is a new & disruptive beverage carrier which is sustainable, durable and returnable. Aim ing to replace cardboard boxes and plastic crates, the Gladiator brings the best of both worlds.

Formcore – PEER Chair — Airex (Switzerland)

Formcore is a core material technology, developed for the production of free-formed sandwich elements without the support of costly molds or tools.

Mass-produced flax fiber roofs — Mecelec (France)

The first application of flax fiber BMC for mass production. The Morris column dome, was designed, tested & launched in under a year.

Category VI. Maritime Transportation and Shipbuilding

Rotor sail lightweight solution from Gurit UK Ltd.

Structural Flow Media for infusion process — Chomarat (France)

G-FLOW is an internal flow media made with 100% glass fibers for infusion process. Its innovative design brings unprecedented flow performance and superior mechanical properties.

Norsepower Rotor Sail Lightweight Solution — Gurit UK Ltd. (U.K.)

Norsepower Rotor Sail Solution, helps freight and passenger vessels to reduce fuel costs by 5-30 %, by enhancing the propulsion system of a vessel by using wind as an auxiliary propulsion measure.

Design-for-disassembly of bonded composite foils — RESCOLL (France)

Composite foil for motor boats that can be bonded to the engine to increase the amount of lift produced at the stem and debonded-on-command to allow engine maintenance, reuse or upgrade.

Category VII. Process

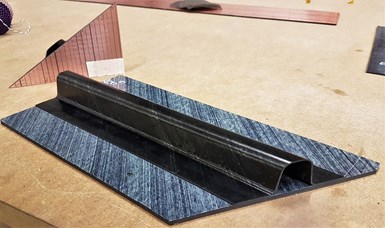

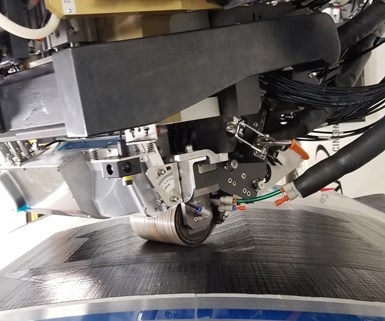

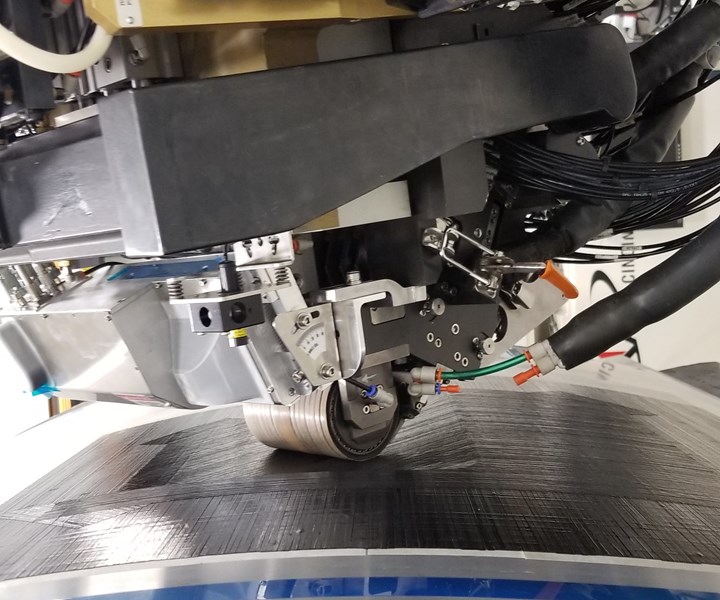

In-process AFP inspection solution from Fives and the National Research Council of Canada (NRC)

Functional paint films for composite manufacturing — Corso Magenta (France)

In mold application of dry paint film, primer or topcoat, leading to a drastic reduction of cycle time, lower environmental impact, and new functionalization opportunities.

Line for tailored Thermoplastic Composite Blanks — ENGEL AUSTRIA (Austria)

The line, consisting of a pick-and-place stacking cell and a heating- and-cooling consolidation unit, is capable producing a tailored thermoplastic blank within a cycle time of one to three minutes.

In-Process Inspection for AFP — FIVES MACHINING (France)

The Fives/NRC In-Process Inspection Platform is based on an innovative measurement sensor and real time processing software pipeline which facilitates responsive monitoring of the AFP layup process.

Category VIII. Railway Vehicles and Infrastructure

COHLE carbon catenary composite light rail system

COHLE Carbon Catenary Composite Light Rail System — Cecence Ltd. (U.K.)

A composite overhead line catenary system for Light Rail utilizing carbon fiber allowing for an increased aesthetic through a 50% reduction in support poles and no requirement for a tensioning system.

Project BRAINSTORM — Far-UK Ltd. (U.K.)

Light rail getting lighter! Very lightweight composite tubes in a novel design for light railcar structures produce lower investment and manufacturing costs, as well as reducing carbon emissions.

DESTINY Thermoplastic resin Train Front end — Stratiforme Industries (France)

The DESTINY project aims to launch a new range of components for commercial aircraft interior fittings and rail applications based on thermoplastic composites.

Category IX. Recycling

Cobra and Aditya Birla Chemicals infused epoxy mold tool and thermoset epoxy RTM watersports fin

Closed Loop Recycling of Epoxy Composites — Cobra international Co. Ltd. (Thailand)

Cobra and Aditya Birla Chemicals present a sustainable solution for closed loop recycling of infused epoxy mold tools and thermoset epoxy RTM watersports fins for Starboard and MFC.

Catering Standard Unit in modular composite design — Comprisetec GmbH (Germany)

The use of special developed SMC enables a weight reduction combined with longer lifetime due to improved robustness. In addition the use of recycled carbon fibers lowers the environmental impact.

Ultimate Speedboard — University of Applied Sciences and Arts Northwestern Switzerland (Switzerland)

The product developed is a sole construction for a performance running shoe made out of sheet molding compound (SMC) with recycled carbon fibers from previous aerospace and automotive applications.

Category X. Space

Satellite structure with ampliTex and powerRibs — Bcomp Ltd. (Switzerland)

A demisable satellite structure panel made from high-performance ampliTex and powerRibs bio-composite technologies, that meets the stringent requirements of the space environment at TRL5.

Lightweight & Liner-less Carbon Subscale Cryotank — Hankuk Carbon Ltd. (South Korea)

Achieved 30% of the space launch vehicle weight reduction by replacing the current fuel tank to renewal liner-less carbon composites cryotank.

Flax-based thermal protection for space launcher — Linéo SAS (France)

This innovation is an external thermal protection for space launcher made of composite material based on flax fibers. It is a breaking technology to meet environmental requirements and to reduce costs.

Category XI. Sports and Healthcare

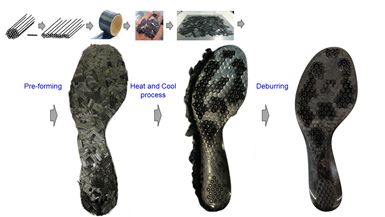

ASICS spike-less CFRTP sprinting shoes

Amparo Confidence Socket —Amparo GmbH (Germany)

Amparo is redefining prosthetic socket technology. Confidence Socket is an innovative off-the-shelf product, that was created to provide a simpler, faster and more economic fitting process.

Spike-Less CFRTP Sprinting Shoe —ASICS Corp. (Japan)

A breakthrough shaping methodology using pre-formed randomly- oriented ultra-thin CFRTP tapes: Result=finest detail molding is now possible with CFRTP as accomplished in this spike-less sprinting shoe.

Automated production hybrid composite bike frames — REIN4CED (Belgium)

Intelligent & optimized composite design capabilities with innovative hybrid material concept for tough composites. Fully automated production process for cost-efficient high-performance CFRTP parts.

.jpg;width=70;height=70;mode=crop)