Design & Tooling

Bercella, Formula Seven target motorsport innovation with natural fiber composite developments

AmpliTex flax fiber used to develop Formula SAE single-seater racing seat for better resistance, vibration absorption and reduced environmental impact.

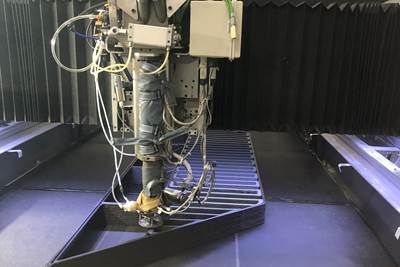

Read MoreCincinnati Inc. BAAM printer demonstrates 3D printing with recycled composites

Dual-material thermoplastic extrusion system produces monolithic composites tool exceeding 10 feet in length, without manual intervention.

Read MoreCEAD and Belotti make large-scale additive composites manufacturing accessible for industry

Strategic partnership combines expertise of additive and subtractive manufacturing into single hybrid solution: BEAD.

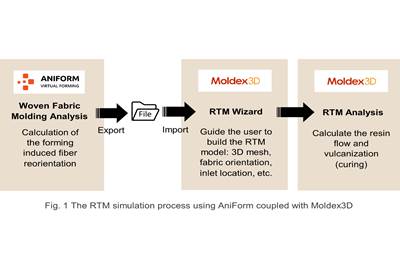

Read MoreAniForm, Moldex3D develop interface tool for more accurate RTM prediction analysis

Interface enables users to consider forming-induced fiber reorientation in the RTM simulation model for a more accurate representation of the flow domain.

Read MoreRoyal DSM, MKU composite armor protects Brazilian law enforcement

Level IIIA soft armor vests use Dyneema UD material for 35% weight reduction, and rigorous compliance with NIJ standards for protection against ballistic materials.

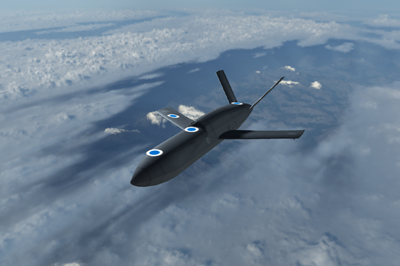

Read MoreSpirit AeroSystems Belfast advances LANCA project concept with resin transfer infusion

Spirit AeroSystems Belfast, Northrop Grumman and Intrepid Minds support further development of the Royal Air Force’s unmanned Lightweight Affordable Novel Combat Aircraft (LANCA).

Read MoreCobra International rapidly scales up Radinn glass fiber electric surfboards

Cobra manufacturing platform to deliver 300 composite boards per month, with 25% weight savings, tight tolerances, detailed QC and documentation records.

Read MoreNorthrop Grumman contributes key composite structures for ULA Delta IV rocket launch

Eleven composite structure such as composite thermal shields, interstage, payload, propellant tanks, produced via hand layup, machining and inspection techniques supported the successful launch.

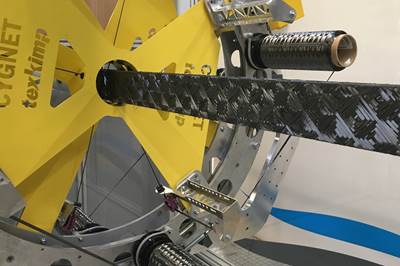

Read MoreNWCC, Cygnet Texkimp collaboration to advance data on winding capability for composite parts

Research project to demonstrate damage tolerance and impact resistance of composite parts manufactured with new multi-axis winder and 3D winding technologies for further development and commercialization.

Read MoreAZL to carry out ultra-fast consolidator machine and inductive double-belt press developments

Innovative systems demonstrate highly scalable and flexible consolidation of composite laminates. Follow-up projects to be carried out this year.

Watch