CAMX 2021 exhibit preview: Calyxia

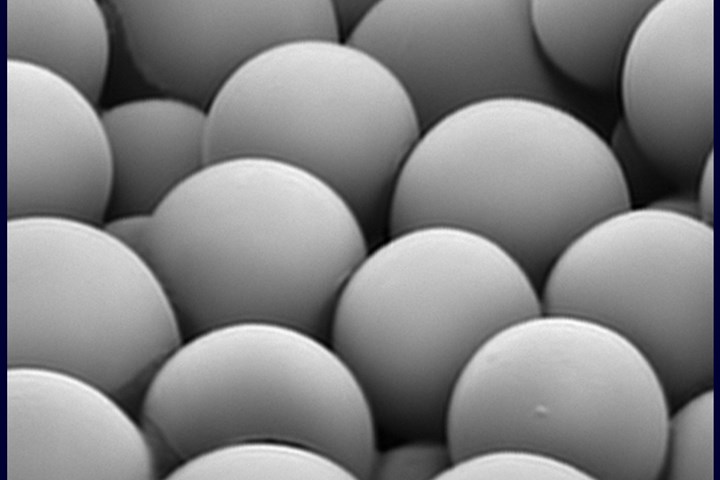

Calyxia's microencapsulation technology can protect reactive, functional and optical additives even in extreme temperature and shear processing conditions.

(Bonneuil-sur-Marne, France) has developed a microencapsulation technology and process to produce what the company says are the first sealed, process-resistant and customizable microcapsules. According to Calyxia, this technology expands the performance potential and the scope of use of specialty chemicals.

Calyxia says its technology can protect reactive, functional and optical additives even in extreme temperature and shear processing conditions (extrusion, injection, compression molding, film casting).

More specifically, Calyxia technology can protect process additives (catalysts, accelerators, curing agents) from premature reaction during processing, and then deliver the additive on command during curing. This reportedly provides a significant advancement in terms of process and performance control. In addition, the Calyxia technology can protect functional additives (anti-wear, anti-abrasion) against degradation, cross-reaction or instability during processing. Anti-wear/abrasion additives are then delivered only in the event of wear or abrasion. Calyxia says functional additives enhance both the performance and the lifetime of the final product. Calyxia’s microencapsulation technology is also able to fully protected optical additives (pigments, liquid crystals, dyes) throughout the lifetime of the product.

Calyxia says its microencapsulation technology has been successfully validated with many large actors in high-performance plastics, electronics materials, adhesives and coatings applications to provide new features to materials or improve the performance of current materials.

Related Content

-

Concentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

-

Prepreg range targets versatility, low CO2 impact

CAMX 2025: Prepreg partner SHD Composite Materials supports tooling, component and structural needs with resin system solutions like FR308 and MTC400-1.

-

Maximize your experience: CAMX 2025 exhibit previews, Part 1

This list of 90+ exhibitor previews solicited by CW offers a glimpse into the various technologies, emerging trends and solutions attendees should look for on the CAMX show floor.