Pultrusion

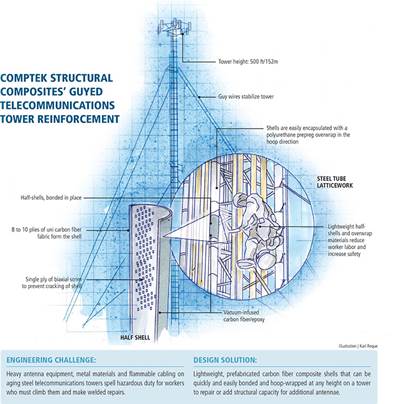

Composites the clear choice in telecom tower rehabs

Tower permit difficulties spur repairs/upgrades of aging steel structures.

Read MorePolyurethane pultrusion: Next-gen equipment

Two years ago, Martin Pultrusion Group (MPG, Oakwood Village, Ohio) finalized the design of a next-generation pultrusion machine and has developed a proprietary direct injection box design for high-pressure pultrusion of polyurethane composites.

Read MorePultruding polyurethane: Sheet pilings break boundaries

High-pressure pultrusion process creates polyurethane composite sheet pile system with the strength and stiffness to compete with steel.

Read MoreFire destroys window/door pultruder’s plant

Pultruder Omniglass Ltd.’s manufacturing facility in Winnipeg, Manitoba was destroyed by fire in January of this year.

Read MorePultruded windows: Rising high?

New pultrudable glass fiber/resin formulations enable window manufacturers to break in to commercial architecture and build market share in residential construction.

Read MoreA hidden revolution: composite rebar gains strength

Fiber-reinforced plastic (FRP) replacing coated steel in more reinforced-concrete applications.

Read MoreSmall wind gets big

Massive growth, complex blade designs reopen challenging market in wind energy niche.

Read MoreNew filament to make composites "smart"

CW Conferences director Scott Stephenson premiers a showcase for new ideas overheard at CW Conferences.

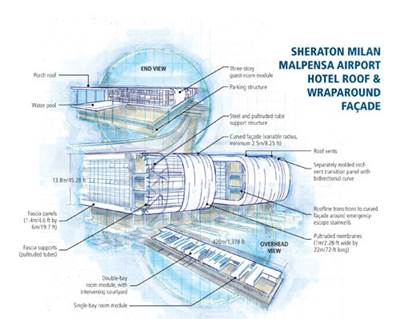

Read MoreHotel wrap: Curvilinear pultrusions

Airport hotel’s striking wraparound roofline made possible, durable and affordable with pultruded flat panels and profiled support structures.

Read MoreStructural makeover: Big bridge-strengthening project

The 2.5-km/1.6-mile long cable-stayed-concrete West Gate Bridge in Melbourne, Australia, is prepped for added traffic lanes with BASF's MBrace composite reinforcements, pultruded by EPSILON Composite (Gaillan-en-Médoc, France).

Read More