Pultrusion

How Are Composite Bridges Performing?

Ongoing monitoring and inspection demonstrates that composite bridge decks meet or exceed expectations.

Read MoreAdvanced Pultrusion Takes Off In Commercial Aircraft Structures

Innovative prepreg pultrusion process forms profiles equal to autoclaved components at lower cost.

Read MoreVinyl Esters Make Tough Parts For Highly Corrosive Applications

An array of case studies showcases the growing acceptance of fiberglass/vinyl ester composites in harsh industrial environments.

Read MoreOffshore Applications: The Future Is Now

The number of composites installations continues to grow on new and existing offshore facilities.

Read MoreNew Lightweight Trailer Delivers Heavy-duty Performance

All-composite chassis and trailer design offers truckers increased cargo capacity plus greater durability.

Read MoreAll-Composite Platforms?

Gibson describes how a team representing the Centre for Composite Materials Engineering, MSP (formerly Maunsell Structural Plastics, Beckenham, Kent, U.K.) and Odebrecht Oil and Gas, a Brazilian-owned platform fabrication company, were tasked with redesigning the topside of BP’s small, minimum-facility Davy-Be

Read MoreDesign Issues With Tendons

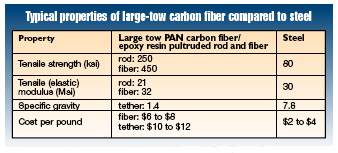

A composite tendon is essentially a rope made from small-diameter rods, which are pultruded with carbon fiber. Multiple rods are gathered together and twisted slightly to form a strand, using typical wire rope stranding methods. Depending on the performance requirements, 10 to 40 strands, about 2 to 3 inches/5

Read MoreSome Design Issues

A variety of resins can be used for offshore applications, depending on the requirements for the final product. General-purpose polyester offers a low-cost option that provides greater corrosion resistance than steel. Isophthalic polyester provides somewhat better corrosion resistance, while vinyl ester is pre

Read MorePetrobras Pioneers Topside Composites

Petrobras (Rio de Janeiro, Brazil) was the first major oil company to experiment with molded gratings in the 1980s, though these early products proved unsatisfactory due to wide variations in mechanical properties. However, advances in pultrusion and filament winding technology coupled with the availability of

Read MoreComposite Tether Goes To Sea

Conoco and KOP have manufactured a prototype of a carbon fiber composite tether that could extend TLP production to depths exceeding 10,000 ft/3,000 m. The design has undergone extensive static testing and fatigue loading and has been verified through hydrodynamic model testing. Sea testing is being planned.

Read More