Pultrusion

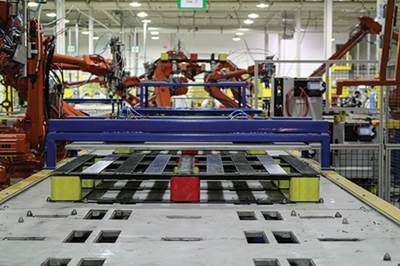

Pultruded polyurethane pallets

Composite solution transforms wooden consumable into profit-generating asset.

Read MoreAutomated composites manufacturing, past, present and future

CW guest columnist Rob Sjostedt is a partner and CEO at VectorSum Inc. He recalls his days at Goldsworthy Engineering and reminds CW readers that today’s product requirements are more challenging than ever, and creative new approaches are required.

Read MoreYachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

Read MoreLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read MoreIncremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

Read MoreFabrication methods (2015)

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MorePultruded window: Glass/polyurethane prototype wins award

Deceuninck Group NV (Hooglede-Gits, Belgium), is at the forefront of composite window frame design and innovation, as evidenced by its recent award for a large, prototype window designed to open like a door.

Read MoreDisaster-resistant housing: Framing the future

This need in developing nations could be met by a composite structural framing system capable of producing both fortified dwellings and jobs.

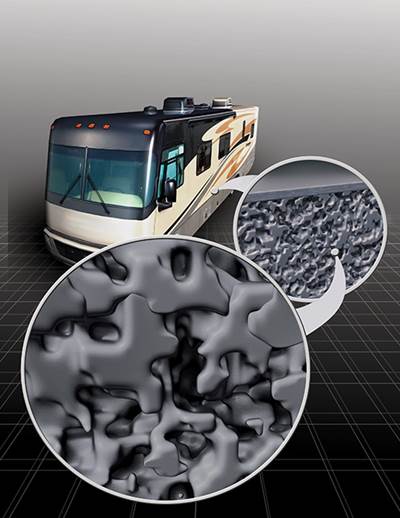

Read MoreMass reduction for mass appeal: FRPs and CMCs in RVs

Composites save weight, speed assembly, improve aesthetics and diminish warranty service and promote sales.

Read MoreDon’t call it a blimp!

The builders of this variable-buoyancy craft count on carbon fiber/epoxy trusswork to enable a new era of air transport.

Read More

.jpg;maxWidth=400;quality=70)