Pultrusion

VELOX, Ilium Composites now partners

VELOX GmbH a European distributor of raw material specialties for the composites industry, has formed a new distribution partnership with Ilium Composites, a manufacturer of glass reinforcements.

Read MoreCW Talks: How carbon fiber beat out steel in elevator cabling

CW Talks: The Composites Podcast learns from KONE’s Steve Gonzalez how pultruded carbon fiber UltraRope was developed to help move elevators up and down in the world’s tallest buildings.

Read MoreRail line landmark restoration via pultrusion

Composites’ corrosion resistance ensures preservation.

Read MorePultrusions growing in construction: new EPTA report

There’s a new report out from EPTA (European Pultrusion Technology Assn., Frankfurt am Main, Germany) that discusses new trends for pultrusion in building and construction.

Read MoreKraussMaffei doubles pultrusion speed and continued developing composites processes for large series production

New iPul pultrusion system doubles production speed while intelligent automation cuts cycle time in FiberForm and RTM processes.

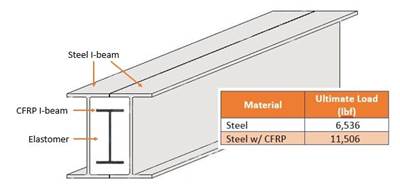

Read MoreSuperbeam: Steel and carbon fiber work together to revolutionize structural elements

New approach to CFRP-strengthened steel beams increases load capacity by >75%, enabling dramatic downsizing while maintaining traditional bolted and welded attachments.

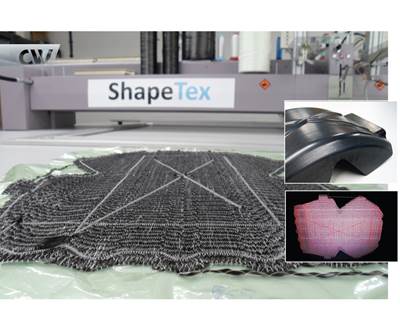

Read MorePreforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

Read MoreComposite musings

How do we generate pull from consumers rather than depend on push through builders and contractors?

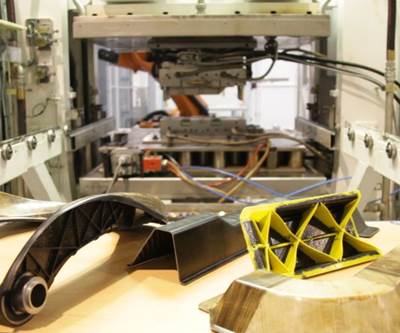

Read MoreAutomated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

WatchComposites bridge the gap in an historic nature trail

Partially pre-assembled pultruded parts helicoptered in for quick, nature-sensitive assembly.

Read More