KraussMaffei doubles pultrusion speed and continued developing composites processes for large series production

New iPul pultrusion system doubles production speed while intelligent automation cuts cycle time in FiberForm and RTM processes.

Krauss-Maffei’s (Munich, Germany) new iPul system had its successful live debut during the KraussMaffei Competence Day Pultrusion at the end of June. The new iPul pultrusion system is the first complete system for continuous pultrusion of straight and curved profiles. Featuring production speeds up to two times faster than the conventional tub or pull-through process, it opens up completely new markets for pultrusion.

In pultrusion, continuous glass, carbon or aramid fibers are infiltrated with a reactive plastic matrix and formed to the desired profile in a heated mold. Grippers pull the cured profile continuously and feed it to a sawing unit. KraussMaffei’s new iPul system encompasses this entire sequence, revolutionizing long-time pultrusion technology in two respects. It encapsulates the infiltration of the fibers — which, until now, has mostly occurred in open vessels — in a closed injection box, which permits the use of fast-reacting systems including epoxy, polyurethane and polyamide 6. And it increases the production speed from the usual 0.5 - 1.5 m/min to approximately 3.0 m/min.

Thermoplastic lightweight construction is up and coming

KraussMaffei has also continued to develop its other composite processes, such as FiberForm, which thermoforms and overmolds organosheet – i.e., semifished thermoplastic composite products with continuous glass, carbon or aramid fibers that are embedded into a thermoplastic matrix such as polyamide (PA), polypropylene (PP), etc. In this process, these semifinished products are first heated, reshaped in the injection mold and then back-injected with polymer, with or without fiber reinforcement.

"Since the market launch at the K 2010, we have consistently further developed the FiberForm technology, and today we offer our customers a series production solution," explains Stefan Fenske, FiberForm Technology Manager with KraussMaffei. New for the KraussMaffei FiberForm system is, for example, the concept of automation. The heating of the composite sheet and the demolding of the finished component take place in parallel, and the individual process steps are thus decoupled from one another. In addition, the infrared heating station required for heating up has been mounted directly above the mold parting line and—as a result—the transfer time of the composite sheet into the injection mold is reduced to a minimum. Overall, the FiberForm system provides its users with extremely robust processes, high availability and the efficiency required for high-volume series projects.

Five different RTM processes

Also continuously improved for short cycle times, high reproducibility and a high degree of automation are KraussMaffei’s five different resin transfer molding (RTM) processes. High pressure RTM (HP-RTM) allows the manufacture of extremely lightweight structural components that also withstand requirements such as extreme dynamic load conditions in a car crash. In compression RTM (C-RTM), the addition of resin — usually epoxy or polyurethane — is carried out in a slightly open mold, yielding parts with over 50% fiber content but with a paintable surface. Wet pressing does not inject resin, but instead uses a simplified process chain—the preform process is completely omitted – applying resin directly onto reinforcements which are subsequently pressed, and offers a cost-effective alternative for manufacturing high-volume, lightweight vehicle components. The thermoplastic RTM (T-RTM) injects thermoplastic matrix systems, including very low-viscosity monomers such as caprolactam, which then in situ polymerizes to form a PA6 (Nylon 6) composite. Advantage: The components are recyclable at the end of the product life cycle and, unlike common thermoset plastics, can also be formed or welded in downstream process steps.

Related Content

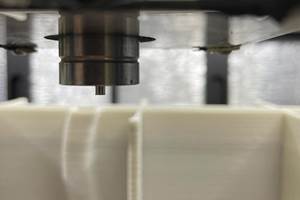

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Read MoreAES explores robot vs. gantry for large-format additive manufacturing

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More