Molds/Tools

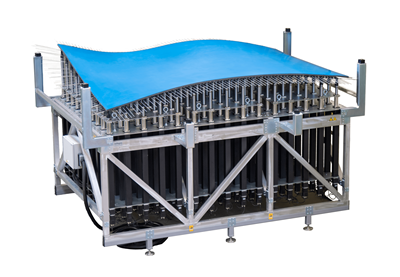

Adapa announces Curve Works as new co-investor

Curve Works owner Dr. François Geuskens is taking a proactive management role as Adapa’s CTO to continue broadening the functionality, application of the company’s adaptive mold system.

Read MoreBase Materials showcases Ares 770 tooling material

Ares 770 is designed for the manufacture of master models and patterns used in the production of carbon fiber parts, as well as vacuum forming and thermoforming.

Read MoreMetal AM advances in composite tooling, Part 1

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

Read MoreBase Materials launches BE368 epoxy tooling board

Medium-temperature material is designed for the manufacture of master models, patterns, jigs and fixtures.

Read MoreMassivit 3D wins IBEX Innovation Award for additive composite tooling system

The Massivit 10000 provides automated, high-speed tooling for composite materials manufacturing, finds foothold in marine industry.

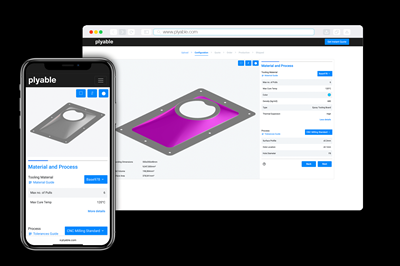

Read MorePlyable secures $3.2 million investment to advance custom composite marketplace solution

Funding from Maven Capital Partners, Solvay Ventures and VC Forward Partners backs growth of time- and cost-saving digital composite tooling product.

Read MoreCAMX 2022 exhibit preview: Symmetrix Composite Tooling

Symmetrix Composite Tooling highlights its high-quality sub-millimeter-accurate composite tooling services and its ability to undertake a wide variety of projects.

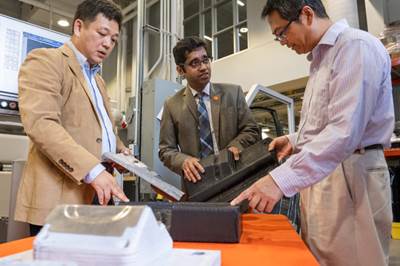

Read MoreClemson Composites Center leads research in low-cost composite tooling

Innovative technology approach to use additive manufacturing and artificial intelligence to produce tools faster, at a lower cost and with less environmental impact.

WatchComposites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

WatchSolvay launches LTM 350 low-temperature composite tooling prepreg

Carbon fiber epoxy prepreg sets new standards in cost-efficient composite tooling with fast layup, fast initial cure and short post-cure cycles.

Read More