Molds/Tools

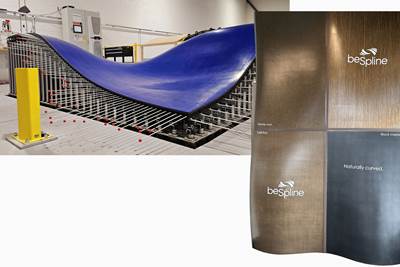

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreBelotti retrofits Vega CNC center in BEAD hybrid machine for D-Composites

Combined LSAM and five-axis CNC milling capabilities will optimize D-Composites’ production services, flexibility and cut time and cost for composite tooling manufacture.

Read MorePRF Composite Materials granted U.K. patent for Q.tool

Innovative prepreg tooling is highly drapable, capable of forming complex carbon fiber tooling shapes, in addition to reducing through thickness porosity and only requiring one debulk during layup.

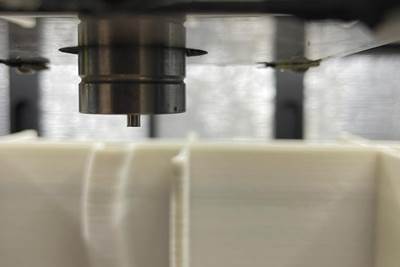

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

WatchORNL conducts sustainability analysis of 3D-printed composite molds

A comprehensive lifecycle, cost and carbon emissions study on carbon fiber molds, produced for New York’s concrete Domino building, cites economic benefits over wood alternatives.

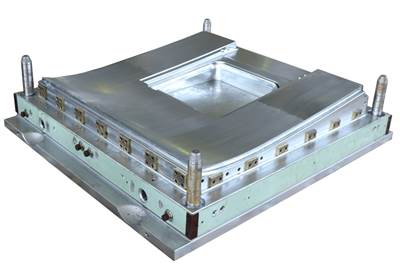

Read MorePrecision composite molds produce quality, reliable parts

CAMX 2023: Suase, under the Sanse Group, is presenting its design, development and manufacture of high-quality SMC/BMC/GMT/LFT molds for automotive, agriculture, construction, rail and more.

Read MoreAdvancing composite manufacturing through custom wire solutions

CAMX 2023: Pelican Wire’s engineering and manufacturing capabilities provide tailored wire solutions for complex heating, temperature monitoring and distinct sensing applications.

Read MoreTechnology investment contributes to complex industrial tooling services

CAMX 2023: A new five-axis router rounds out Accurate Patterns’ capabilities in precise toolmaking, patterns, plugs, fixtures and gauges for fiberglass fabricators, thermal formers, carbon fiber parts manufacturers and others.

Read MoreComposites UK launches best practice guide for composites tooling

“Mould Tooling for Fibre-Reinforced Polymer Composites” is latest in Composites UK’s series of good practice guides, available online for free.

Read MoreBase Materials announces new distributor to support growth in European composites market

B. Beyer GmbH will distribute Base Materials’ range of epoxy and polyurethane tooling board materials and ancillary products.

Read More