Belotti retrofits Vega CNC center in BEAD hybrid machine for D-Composites

Combined LSAM and five-axis CNC milling capabilities will optimize D-Composites’ production services, flexibility and cut time and cost for composite tooling manufacture.

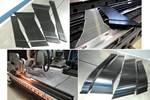

Belotti BEAD retrofit. Photo Credit, all images: Belotti SpA

Leveraging the full potential of BEAD, a hybrid machine combining large-scale additive manufacturing (AM) and CNC machining, Belotti (Suisio, Italy) is helping its composites customers expand production capacity and other opportunities, such as (Radviliškis, Lithuania), which recently retrofitted a Belotti Vega CNC machining center purchased back in 2018 with the all-in-one gantry BEAD machine to extend its aerospace application capabilities.

What is BEAD?

BEAD, the result of a partnership with composites AM specialist CEAD (Delft, Netherlands), integrates 3D printing with five-axis CNC milling in a single machining center, combining the speed and creative potential of the former, with the precision and reliability of the latter. Through an easy, complete integration of a CEAD extruder for large-scale additive manufacturing (LSAM) in a Belotti five-axis CNC, enables the production of parts that are sufficiently oversized to be finished to the required tolerances with reduced raw materials consumption and time completing the part compared to more traditional methods.

BEAD machines are provided in different configurations, with variable build volumes, extrusion outputs and printing orientations (learn more about the machines ). Some units have been supplied to and installed at Belotti European customer facilities as new machines or as retrofits on existing Belotti CNC centers, like D-Composites, while new applications and pilot projects are constantly tested at Belotti headquarters in Italy.

Retrofitting the Belotti Vega

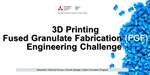

D-Composites is a Lithuanian company with a wealth of experience in the design, manufacture, assembly and supply of complete engineering solutions for composite materials and metal parts. The retrofit of its 8,000 × 3,200 × 2,000-millimeter machine with a CEAD S25 3D printing extruder has enabled the company to expand production services for the aerospace, automotive and composites tooling industries, obtain greater production flexibility, and save time and costs on traditional applications.

“For model production we use Belotti Vega Series CNC machining centers which are the best for production of aluminum, composite materials and resin milling applications,” says Ilja Poteskins, D-Composites product manager. “This concept represents the answer to the high demand of the aerospace, marine and automotive fields and in general the major pattern makers and composite parts manufacturers.”

Retrofitting involved the upgrade of the old machine numerical control, to enable the addition of new functionalities needed for extrusion process management, as well as integration of the extruder cabling system. Being a Siemens-controlled machine, the operator is able to monitor process parameters directly from the panel of the gantry system as if it were a brand new BEAD machine.

D-composites crew with Belotti SpA and Airtech specialist at installation.

The addition of the S25 extruder, a lightweight solution with a maximum output of 24 kilograms/hour, enables D-Composites to program complex extrusion paths based on optimal printing orientation and final material properties. Extrusion output can process a wide range of thermoplastic materials, from commodities, extensively used for low-temperature applications, like PP, PETG or ABS, to high-performance materials like fiber-filled PA6, PC, PEI or PESU, able to sustain up to 200°C service temperatures. It can also manage different types of fibers as reinforcement, from glass to carbon and natural fibers.

This new hybrid machine (Belotti Vega 8032 plus 3D extruder) will be used for the manufacture of tools for composite production, from fixturing jigs to master models and direct molds for automotive, marine and aerospace industries. D-Composites’ goal is to reduce internal production times and costs of composite components — both for glass- and carbon fiber-filled parts, as well as for composite tools for its own customers.

D-Composites was further aided by composite materials supplier, Airtech Advanced Materials Group (Huntington Beach, Calif., U.S.), which has provided invaluable technical support from the first customer approach with the 3D printing system, guiding D-Composites from the choice of materials to the printing strategy to optimize product shapes and properties.

After the retrofit service, a complete training session was provided to D-Composites regarding new features, functions and operating modes of the hybrid gantry system; in fact, Belotti notes, this is a key service of every Belotti technology.

Related Content

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreReinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreRead Next

CEAD launches new E50 Robot Extruder for larger 3D-printed composites

New option offers higher material output (e.g., 84 kg/hr) and thermoplastic melt temperatures up to 400°C.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreMitsubishi Chemical Group launches 3D printing FGF engineering challenge

The open AM innovation program welcomes all interested parties who would like to make use of the potential of 3D printing FGF or combine it with materials like carbon fiber, UD tape and other hybrid technologies.

Read More