Molds/Tools

Big museum, big structures

Massive aramid/carbon composite sandwich panels make Amsterdam’s Stedelijk Museum the largest composite-clad building in the world.

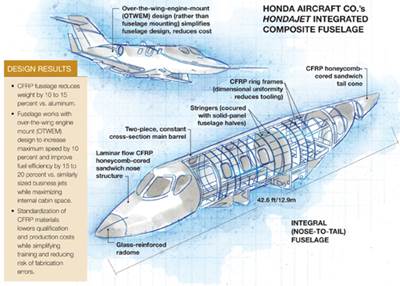

Read MoreComposite fuselage helps HondaJet upend biz-jet market

CFRP composites enable unitized structure with low-drag aerodynamics that transform aircraft performance and reduce cost.

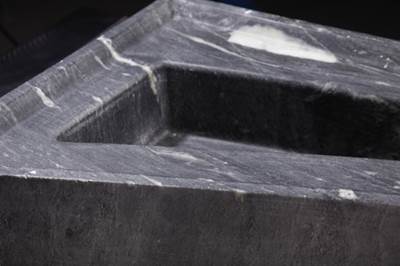

Read MoreTooling block makes affordable patterns for new superlight aircraft

Tooling for a new canard-winged pusher airplane, the e-Go (e-Go Airplanes of Cambridge, U.K.), was created from patterns made of EP678 epoxy tooling block, supplied by the Advanced Engineering Materials Product Group of Trelleborg Offshore UK (Skelmersdale, Lancashire, U.K.)

Read MoreThermoplastic Wind Blades: To be or not?

Will future wind blades incorporate thermoplastic composites? It depends on whom you ask.

Read MoreBig parts? Big tooling breakthrough

Electrically heated carbon fiber/PEEK/ceramic tooling and powdered epoxy resin system could revolutionize production of large composite aerospace structures.

Read MorePatented MECHTool system

Galway, Ireland-based ÉireComposites’ patented MECHTool (Mold Efficient Cooling and Heating) system was developed to replace traditional ovens in a number of thermoplastic molding processes.

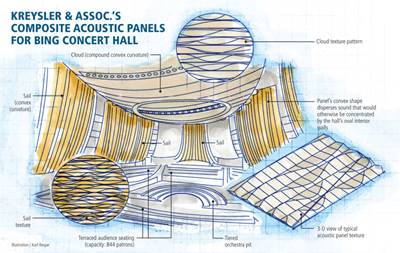

Read MoreConcert hall composites: Acoustic alchemy

Massive composite acoustic structures will reflect and diffuse sound to heighten audio quality in a new high-profile performance space.

Read MoreTooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

Read MoreTooling boards improve processes

In the composites industry, many parts are the product of one-off or few-of-a-kind production programs. In response, tooling material suppliers today provide an increasing variety of relatively inexpensive materials grouped under the heading of tooling board.

Read MoreNew options for trapped tooling

Trapped tool removal can be difficult, but leaving the tool in place can compromise part weight and function. Here, HPC reports on several new approaches to this demolding dilemma.

Read More