New options for trapped tooling

Trapped tool removal can be difficult, but leaving the tool in place can compromise part weight and function. Here, HPC reports on several new approaches to this demolding dilemma.

Trapped tools, those used to provide support on the inside walls of hollow parts, often present part designers with the problem of postcure tool removal. Tool removal can be difficult, but leaving the tool in place can compromise part weight and function. Here, HPC reports on several new approaches to this demolding dilemma.

Smart Tooling, a trademarked product of Spintech Ventures LLC (Xenia, Ohio), uses fiber-reinforced shape memory polymers (SMPs) as a trapped tooling solution for aerospace applications and other markets. The company’s reusable Smart Mandrels and SMP Bladders are less-expensive alternatives to silicone bladders and washout materials as well as multipiece tooling that must be disassembled for removal. Further, they are quicker and easier to use, claims chief technology officer Ernie Havens. “They are also amenable to automation and faster layup processes for lower manufacturing cost,” he adds.

A Smart Mandrels blank (fiber-reinforced SMP formed into hollow tubing) is placed into a two-part mandrel mold and heated to soften the blank; when softened, the mandrel is pushed against the mold contours with air pressure. After it is cooled, the SMP becomes rigid and maintains the molded shape. The rigid mandrel is then coated with a mold release and used for layup of a composite part; the part, during cure, is heated to 250°F/121°C, which is below the mandrel’s transition temperature, says Havens. Then, the mandrel is reheated to above its softening temperature (more than 250°F). It resumes its original tube shape and can be extracted from the cured part. The company claims that layup time is significantly reduced when compared to other trapped tooling approaches, which require time to fabricate or wash out. Additionally, disposal of washout residue is not an issue.

The company’s SMP Bladder works similarly but offers compatibility with cure temperatures up to 350°F/176°C. The difference is that the layup is placed into a female tool matched to the outer mold line during cure. Air pressure is applied to the SMP Bladder for consolidation purposes. As the part heats up during cure, the SMP Bladder transitions from a rigid tool to a soft elastic tool, allowing the press operator to use air pressure to further consolidate the layup prior to cure. When the cure cycle is complete, the air pressure is vented and the SMP Bladder shrinks to its original hose-like shape and can be pulled out of the cured part like any other inflatable bladder while the composite remains in the female mold cavity to cool before final demolding.

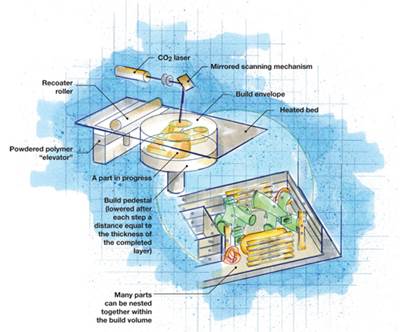

Washout mandrels have been a traditional choice, but Advanced Ceramics Mfg. (Tucson, Ariz.) says it has taken them to the next level, with its RapidCore mandrel manufacturing process, which eliminates mandrel tooling. A mandrel is “printed” directly from the customer’s CAD file, using an additive manufacturing process (see “The rise of rapid manufacturing,” under "Editor's Picks," at top right) and material system, based on the company’s water-soluble materials. When it is complete, the mandrel is coated with a fluoropolymer tape to protect it from water and is then used for part layup. Mandrels can be created in a fraction of the time required for plaster or eutectic salts and possess a compressive strength greater than 100 psi/6.89 bar and a thermal degradation temperature of approximately 350°F/177°C, which is consistent with industry-standard autoclave parameters. After part cure, the RapidCore material is simply washed out with water.

Nevada Composites (Dayton, Nevada) provides warm-water washout mandrels for trapped tooling and traditional single-sided tools, using a moderately priced rapid tooling material, trademarked Green-Aero, based on ceramic microspheres mixed with water-soluble inorganic binders. Lightweight tools are produced via a vacuum molding process in a few days, a process that is speeded by making molds for the mandrels and masters for single-sided tools using an additive manufacturing process, fused deposition modeling. The mandrels and tools have a low CTE and low thermal mass, says company CEO Linda Clements. “By tailoring the tooling material by, for example, varying the particle type and amount or the binder quantity and additives, we can adjust washout properties, improve machinability and mechanical properties, and tailor thermal properties.” Green-Aero is reportedly environmentally benign.

Related Content

Jamco America partners with Airtech for 3DP tool recycling

Aerospace manufacturer joins forces with composite materials company to achieve sustainable manufacturing practices that overcome traditional composite layup tooling.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

Read MoreDLR study considers cast PA6 molds for in situ AFP composites

3D printed thermoplastic mold was analyzed as alternative to expensive, time-consuming metallic molds and for suitability in aerospace-grade composite structure fabrication.

Read MoreTroubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MoreRead Next

The rise of rapid manufacturing

An outgrowth of rapid prototyping, tool-free additive fabrication technologies have the potential to form small, limited-run composite parts directly from CAD data.

Read MoreTooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More