Infusion

GFRP enables first grid-connected U.S. floating wind turbine

Composite tower on 1:8-scale system reduces hull size/weight and helps mitigate the overall cost of electric power generation.

Read MorePublic transit: Modular composites update Sao Paulo ferries

When the Brazilian state of São Paulo, through its state-controlled company DERSA, funded new composite superstructures for 12 existing car ferries, Barracuda Advanced Composites (Rio de Janeiro, Brazil) specified materials and engineered the new design.

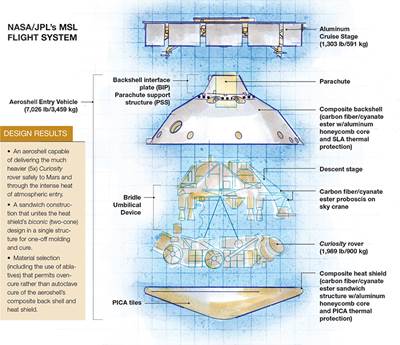

Read MoreComposites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

Read MoreSAMPE Tech Seattle 2014 at a glance

A short compilation of SAMPE Tech Seattle 2014 program highlights.

Read MoreSAMPE Tech Seattle 2014 Preview

The Society for the Advancement of Material and Process Engineering’s annual fall Tech conference is now a spring event.

Read MoreThe Learjet 85: Large step out of the autoclave

HPC editor-in-chief Jeff Sloan examines the significance of the Bombardier Learjet 85’s first flight.

Read MoreQuay cable tray: Composites upgrade container ship terminal

When the Cape Town, South Africa, Transnet National Ports Authority began a 12-month effort to expand its facility and upgrade its existing quays (wharfs), engineers realized that the Authority had a safety problem at its main container quay. Composites provided the solution.

Read MoreHighlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

Read MoreNo-oven, No-autoclave (NONA)

Room-temperature cure epoxy composites with a 400°F Tg, comparable properties vs. commercial systems without external heat or post-cure, and offering reduced cost and cycle time. Really?

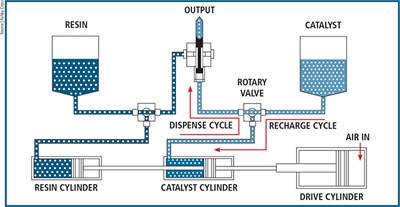

WatchMeter/mix/dispense machines: Doubling down on control

The latest equipment solutions deliver lower costs, faster cycle times and better part properties.

Read More