Infusion

Italian racer uses foam sandwich design, Scott Bader adhesive

Boatbuilder Anselmo Mauri has manufactured Revolver 42, a polyhedric monohull speedboat, constructed using high-permforance composites, including foam core sandwich design and adhesive provided by Scott Bader.

Read MoreComposite solutions: Cutting cost of nuclear-powered subs

Composite-for-metal substitutions cut expense, boost production for Virginia-class submarine program.

Read MoreNew catamaran benefits from structural adhesives, vacuum infusion

Vacuum infusion, SAN sandwich foam cores and structural adhesives help reduce the weight of Mattia's high-performance catamaran yacht by 2,000 kg.

Read MoreSea and land transport: Hydro elevation

Composites lightweight and toughen the hull and superstructure of this transplanted amphibious naval hovercraft.

Read MoreRe-inventing the RHIB: Shock Mitigation

The U.S. Navy’s search for a lighter, load-absorbing rigid-hulled inflatable boat may end with this unconventional design.

Read MoreFiberglass façade: GRP shapes modernize hotel in Spain

The exterior of the Vista Riviera hotel in Benidorm, Spain, has been transformed with a modern twist, thanks to the fiberglass expertise of Miraplas SL (Monforte del Cid, Spain).

Read More3-D preforms: Fast, efficient blade-root manufacture

To expedite the blade root manufacturing process for wind turbine blade manufacturers, 3TEX Inc. (Cary, N.C.) has developed RapidRoot, a 3-D preform.

Read MoreHeavy-duty infusion: Scaling up for scrubbers

Infused 3-D woven fabric preforms best steel in beams and unitized deck structures built for the caustic confines of massive flue gas desulfurization systems.

Read MoreSingle bagging can do the job

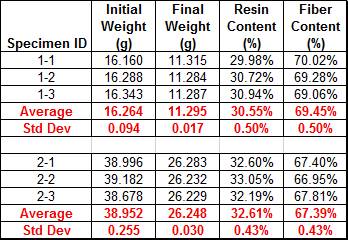

Mechnical engineer Peter Schwarzel (CarbonWorks, Coombabah, Queensland, Australia) comments on the “Engineering Insights” article in the CT December 2010 issue, titled “Double-bag infusion: 70 percent fiber volume?”

Read More