Hi-Temp Resins

Composites at AeroDef 2018

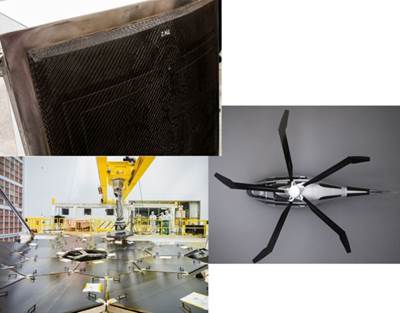

Highlights from the Aerospace Defense Manufacturing Conference – AeroDef 2018 include new technologies for tooling, drilling/machining and inspection of advanced composites.

WatchAFRL pushes limits of polymer additive manufacturing

Air Force Research Laboratory research team has successfully printed the highest-temperature capable, reinforced polymer composite parts.

Read MoreJEC World 2018 preview: Scott Bader

Scott Bader will introduce their Crestafire range of fire, smoke and toxic fume performance products at JEC WORLD in Paris.

Read MoreCarbon Fibre Preforms for low-cost and zero waste

Chopped fiber preforms in seconds, 1200°C burn resistance for hours, low-cost CFRP to replace metals

WatchRenegade recognized for supplier innovation

Renegade Materials was recognized for Supplier Innovation by Meggitt Polymers & Composites Group at Meggitt’s 2017 Global Supplier Conference.

Read MoreCAMX 2017: Highlights from the floor

3D printing and nanotechnology developments promise to cut time and cost in composite structures production while recycling and sustainability continue to grow in importance.

Read MoreRecycling VOCs

Passive reactor turns styrene and phenol/formaldehyde fumes into carbon dioxide and water.

Read MoreCAMX 2017 preview: Renegade Materials/Maverick

Renegade Materials Corp. (Springboro, OH, US) and Maverick Corp. (Blue Ash, OH, US) are emphasizing their composite materials for high-temperature aerospace applications.

Read MorePlant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production.

Read MoreComposites at AIA 2017

The ACMA Architectural Division exhibited its 4th annual Composites Pavilion and 2nd annual COMPOSITES CHALLENGE for architectural students.

Watch