Hi-Temp Resins

Benzoxazine + BMI?

Resin supplier Huntsman Advanced Materials (Basel, Switzerland and The Woodlands, Texas) sees benzoxazine resins as traditional chemistry boundary breakers that open whole new resin-system possibilities.

Read MoreCeramic matrix composites heat up

Lightweight, hard and stable at high temperatures, CMCs are emerging from two decades of study and development into commercial applications.

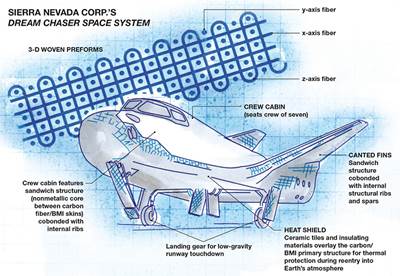

Read MoreU.S. crew and cargo candidate takes shape with composites

Crew-capable Dream Chaser to enable ISS transport missions from U.S.

Read MoreHigh-temp thermoplastics: Higher Expectations

As the drive to greater fuel efficiency under the hood catches fire, fiber-reinforced thermoplastics prove they can take the heat.

Read MoreA new "tunable" polyurethane could revolutionize composites

A novel polyurethane-based resin system with tailorable pot life and cure, from Huntsman Polyurethanes (Auburn Hills, Mich. and Everberg, Belgium) now permits composites manufacturers to tailor resin pot life and onset of cure to fit the processing requirements.

Read MoreComposites enable new advances in engine technology

ÂÌñÏ×ÆÞ's conference director Scott Stephenson recalls a presentation at the recent Carbon Fiber 2010 conference (Dec. 7-9, La Jolla, Calif.) by Doug Ward of GE Aviation (Cincinnati, Ohio) on design trends in commercial jet engines that favor the use of composites.

Read MoreHigh-Performance Resins 2010 Highlights

Inaugural conference for the advanced resins research crowd updates formulators and processors on the latest developments.

Read MoreResins for the Hot Zone, Part II: BMIs, CEs, benzoxazines and phthalonitriles

Next-generation aerospace programs demand higher temperatures for structural and hot-section components, fostering advances in thermoset resin chemistry.

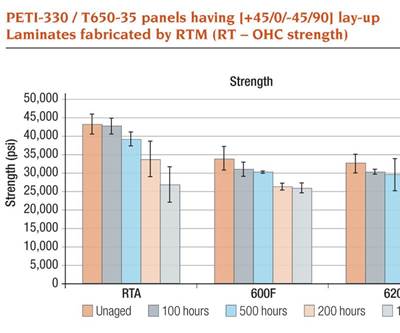

Read MoreResins for the Hot Zone, Part I: Polyimides

As next-generation aerospace programs demand higher service temperatures in structural and hot section components, a variety of polyimides vie for program approval.

Read MoreComposite engine valves?

HPC technical editor Sara Black reports progress on CFRP intake and exhaust valves for race car engines.

Read More