Design/Simulation

Software Update: Simulating a repair

ÂÌñÏ×ÆÞ recently hosted a webinar with Altair’s (Troy, Mich.) Robert Yancey and Tim Harrell, structural analyst, United Launch Alliance (Centennial, Colo.), who discussed the use of Altair’s OptiStruct software to design a doubler repair patch for a rocket motor that was damaged with a gouge defect. “These composite components are very costly, so therefore if a manufacturing default happens, it is advantageous to fix the part,” explains Harrell.

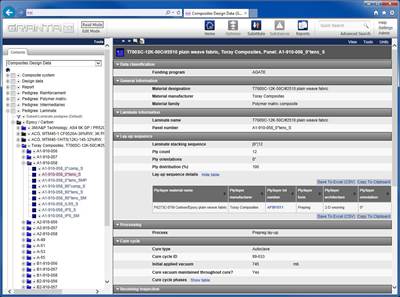

Read MoreSoftware update: Materials database support for simulation/analysis

Another piece of the software integration puzzle in the aerospace world is finding ways and means to incorporate into the design process data from existing materials databases.

Read MoreMIT researchers reveal how bonded joints fracture and fail

Moisture reportedly plays crucial role.

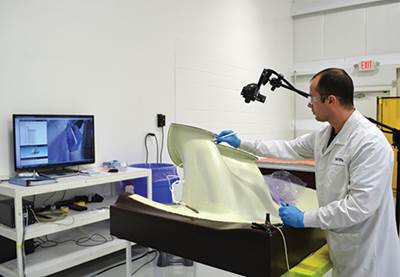

Read MoreCamera-based ply placement cuts time, cost on complex rotorcraft parts

Applied Composites Engineering (ACE, Indianapolis, Ind.) uses PlyMatch ply placement technology from Anaglyph Ltd. (London, U.K.) to speed layup of the complex-shaped, heated inlet for a de-icing system on the AW169 helicopter, from AgustaWestland (Cascina Costa di Samarate, Italy).

Read MoreModeling fabric materials for better parts

Multiaxial fabric maker Formax is involved in a multi-year endeavor to simulate the behavior of dry fabrics during the molding process.

Read MoreDemonstration software modeling exercise aids Taiwan’s yachtbuilding community

Ray Tsai, technical director of Simutech Solution Corp. (Taipei, Taiwan) and colleagues develop a demonstration modeling exercise for Taiwanese motoryacht builders.

Read MoreTwo visions of 3-D printing in CFRP

Freespace Composites and MarkForged pursue different paths to exploit carbon fiber in 3-D printing.

WatchPushing the limits of infusion

Polyworx BV used RTM-Worx, semipermeable membranes, a special feed and vacuum line layout and MMD machines to infuse a 62m minesweeper with degassed resin.

Read MoreVIDEO: Helicopter Drop Test

NASA evaluates composites’ ability to improve helicopter crashworthiness by dropping a helicopter fuselage to simulate a severe survivable crash according to military and commercial transport requirements.

WatchBus station pavilion: A marriage of design and manufacture

Architectural design studio and boatbuilder cooperate to make this passenger terminal "first" a first-class showpiece.

Read More