Pushing the limits of infusion

Polyworx BV used RTM-Worx, semipermeable membranes, a special feed and vacuum line layout and MMD machines to infuse a 62m minesweeper with degassed resin.

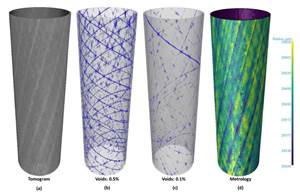

RTM-Worx simulation for infusion of the Oyster 125-ft hull, a single shot using 6300 kg of resin and Polyworx record until the 62m minesweeper. SOURCE: Polyworx BV

(Nijverdal, The Netherlands) develops and licenses the RTM-Worx flow simulation software for resin transfer molding (RTM) and vacuum infusion. In 2011, it worked with SNSZ shipyard (St. Petersburg, Russia) to infuse a 62m/203-ft long minesweeper under a single bag in two steps, guaranteeing the quality of the laminate at the weld lines via a combination of semipermeable membranes, a special configuration of vacuum and resin feed lines, and meter/mix/dispense (MMD) equipment to vacuum degas and inject 20,930 kg/46,143 lb of vinyl ester resin.

One of the first challenges in this project was how to infuse the hull sides, nearly 10m/33 ft tall, including geometrical features. Theoretically, vacuum can raise a column of resin 9.5m/31 ft. However, according to Polyworx owner and director Arjen Koorevaar, "For every meter of height, you lose 100 mbar in vacuum, or roughly 10 percent." Thus, the hull would be infused in two steps, each 5m/16 ft in height: first from the bottom up to the chine, and then from the chine to the top of the hull sides.

In order to provide continuous reinforcement through the 5m line up the hull sides, the dry laminate stack was laid into the whole hull and vacuum bagged, so that both steps would be infused using the same bag. A strip of semipermeable membrane — a thin film or fabric that is permeable to air but not to resin (e.g., Gore-Tex) — was placed around the circumference of the hull sides at the 5m height. (See “Semipermeables: Next Trend in Infusion?” in Feb 2014 CT).

Because the membrane closes when fully wet out, it would stop the resin flow at the desired height. However, when it closed off the air path it would also disable the vacuum, resulting in a pool of resin at the bottom of the hull sides. The solution was a second vacuum line installed below the membrane. This enabled vacuum to lift the resin until gellation, and ensured the flow front continued about halfway up the membrane. Koorevaar describes adding a strip of glass fiber non-crimp fabric to separate the vacuum line from the laminate, “which takes long enough to fill to allow the membrane to do its job and help eliminate the typical porosity where the flow front ends.”

MMD equipment was developed with 2KM Germany (Marienheide-Rodt) to vacuum degas resin one IBC (intermediate bulk container, also called a “tote,” which commonly holds 275 or 330 gallons/1,041 or 1,249 liters) at a time prior to infusion. The MMD machine drew the vinyl ester resin (part A) from the IBC, mixed it with promoter (enabled cure) and inhibitor (provided the 4- to 5-hour open time needed) according to a precise ratio, and then degassed it in two passes, completing 17 IBCs in roughly one week. (See “Meter/Mix/Dispense Machines Doubling Down on Control” in Feb 2014 CT).

Schematic overview of the 2KM degassing and mixing equipment.

Source: Polyworx BV

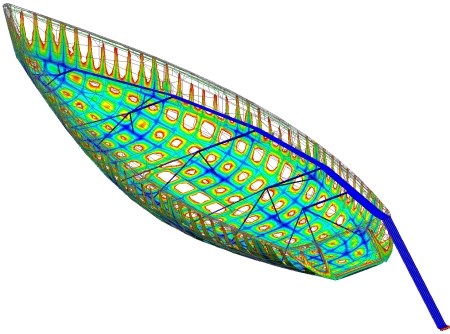

Two additional 2KM machines were designed to mix the degassed resin with the peroxide catalyst (part B) and inject the mixed resin through a 1.5-inch/38mm diameter feed line into a manifold. For the first (lower) infusion, the manifold fed a grid of feed lines that enabled peripheral injection in a set number of “squares” across the span and down the length of the hull bottom. (Vacuum “pickup” points were centered in each square.) For the second “upper” infusion, the manifold fed a “fishbone” configuration of feed lines — one “spine” running the length of the hull, with vertical lines branching off up the hull sides. Koorevaar says the peripheral feed configuration is preferred because it produces the smallest variation in flow front speed, but Polyworx developed the fishbone for large infusions. Each MMD unit used a pressure sensor installed in the feed line manifold. These sent data back to each machine’s computer controller, increasing or decreasing pump speed to maintain ambient pressure and overcome any losses in the 30m/98-ft long “spines.” Two MMD machines were needed to infuse the entire hull length.

Vacuum and feed line setup for a full scale infusion trial.

SOURCE: Polyworx BV

After completing all of the analysis, simulation and a full-scale test section (6m/20 ft long by 8.5m/28 ft high by 10m/33 ft wide), the two infusions were completed successfully on subsequent days: The first took 172 minutes to shoot 14,865 kg/32,772 lb of resin, and the second took 151 minutes to infuse 6,065 kg/13,371 lb of resin. Polyworx also achieved its goal to better understand how semipermeable membranes work and now incorporates this into its computer simulation software.

Interestingly, Koorevaar says test panels were made at SNSZ with the two-shot system and then tested for void content and mechanical properties. The panels showed the lowest void content and highest modulus and interlaminar shear strength at the area that separated the first and second infusions. Pretty impressive.

Related Content

Collier Aerospace HyperX optimizes X-59 composite nose cone

Swift Engineering relied on the CAE software’s structural sizing, analysis and test validation capabilities to deliver flight hardware for NASA’s supersonic QueSST aircraft early, under budget and with 25% weight savings.

Read MoreMulti-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Read MoreTroubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

Aiming infusion at the application

With so many process variables to play with, how do you know which new solutions that promise better, faster infusion are right for your application?

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More