Design/Simulation

Building a bigger Big Wheel

Machining specialist scales up the 1970s icon, producing plugs and tools for an exact fiberglass replica at a Disney resort.

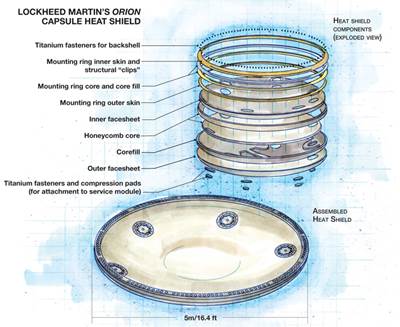

Read MoreOrion re-entry system: Composites displace metal

World’s largest heat shield updates metal design with out-of-autoclave process.

Read MoreIntegrated software: Streamlined hull & tool design

Although its reputation was solid, rigid inflatable boat (RIB) builder Planatech (Athens, Greece) recently sought ways to design new composite products and their corresponding tool sets faster, without compromising quality.

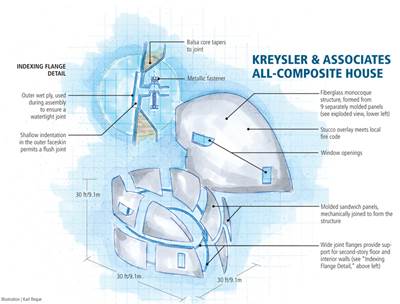

Read MoreResidential construction breakthrough: Composites find a home

Composite materials get the go-ahead for an unconventional but code-compliant California house.

Read MoreVery Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

Read MoreRTM showcase: One-Piece Rudder

A transatlantic design team uses concurrent engineering to integrate rudder spars, ribs and skins in a single RTM cycle.

Read MoreFree-form surfacing optimizes free-style kayak

The 6-ft/1.8m-long Project 54cx kayak, made using aramid and carbon fabric-reinforced composites, weighs only 19 lb/8.6 kg.

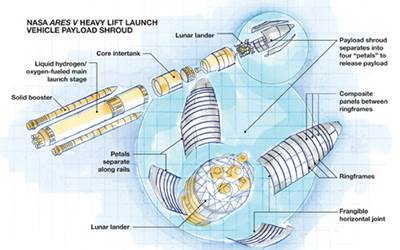

Read MoreOptimizing the Ares V payload shroud

Sizing software allows rapid analysis of candidate composite architecture for highly loaded and weight-sensitive launch vehicle component.

Read MoreSimulation simplifies fabrication of all-composite crew module

Specialized simulation software shortens development cycle on first all-composite crew module demonstrator for NASA space program.

Read MoreDirect manufacturing of military aircraft parts

Laser sintering process shortens lead time, simplifies production of complex, high-performance parts.

Read More