Design/Simulation

Software eases design/build for exotic exercise bike

The Lamiflex Group (Bergamo, Italy) helps Milan, Italy-based design house Luca Schieppati develop the Ciclotte, a striking luxury exercise bicycle made with carbon fiber composites.

Read MoreWater tree: Single complex mold shapes unique composite sculpture

To fabricate a complex design for a lighted sculpture, sculptor Lawrence Argent taps the talents of composites specialists Kreysler and Assoc. (American Canyon, Calif.).

Read MoreDesigning bicycling’s lightest pro racing frame

Cervélo’s Vroomen White Design group combines analysis and manufacturing acumen to create a 675g/1.5 lb composite frame.

Read MoreLife Cycle Assessment resources

A collection of resources for those engaged in Life Cycle Assessment programs.

Read MoreLife Cycle Assessment: Are composites "green"?

Methods for calculating the impact composites have on the environment enable data-driven comparisons to traditional materials on a level playing field.

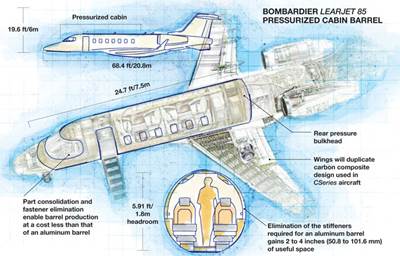

Read MoreLearjet 85 composite pressurized cabin a cost cutter

Single-piece carbon fiber composite structure selected over multipiece aluminum fuselage barrel section in new bizjet design.

Read MoreFuture multifunctional structures: Composites needed

Barton Bennett (Odyssian Technology, South Bend, Ind.) discusses multifunctional systems that will soon integrate composite structures with sensors, mechanisms and subsystems.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read MoreThe digital thread: Transformation to automation

Dr. Leslie Cohen traces the “digital thread” on which automation of composites fabrication processes depends.

Read MoreDigital design, RTM update aircraft propeller

Second-generation type-certified propeller delivers for Cirrus Aircraft’s SR-22 at a more affordable price.

Read More