Design/Simulation

CompoSIDE delivers cost and time saving for composites consultancy

STRUCTeam cites £40,000 savings in licensing costs and up to 40% reduction in design time by using this web-based composites design engineering solution.

Read MoreLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read MoreIncremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

Read MoreGetting part dimensions right in composites molding

Guest columnists Dr. Göran Fernlund (left) and Dr. Anoush Poursartip (right) of Convergent Manufacturing Technologies (Vancouver, BC, Canada) argue that today's CAD design and process simulation software can construct a "multi-physic process model" accurate enough for reliable dimensional management.

Read MoreModeling and simulation: Is ICME the next composites breakthrough?

ÂÌñÏ×ÆÞ columnist and composites industry consultant Dale Brosius encourages empirical learners (read "hands-on, trial-and-error old-timers") like himself to buy in and start using today's software-based design and simulation tools, which, he says, have the "potential to truly transform the composite industry."

Read MoreTools for collecting, managing and using autocomposites data

As the composites universe expands into new markets and applications, resins and fiber reinforcements of many types are, increasingly, landing on the desks of design engineers who have little or no experience with composites.

Read MoreMaterials library seeks composites industry submissions

If you’re a designer for Adidas, Motorola or Toyota, where do you get information about cutting-edge material developments?

Read MoreHaydale acquires EPL Composite Solutions Ltd.

Graphenes and nanomaterials specialist Haydale will acquire EPL Composite Solutions, a specialist in the design, development and commercialization of advanced composites polymer materials in the U.K. and overseas.

Read MoreTurning data into gold

The composites manufacturing environment is awash in data. It's possible to harvest that data and start predicting problems before they occur.

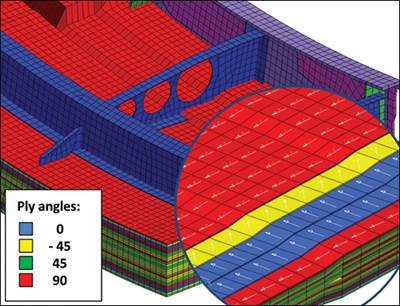

Read MoreSoftware Update: Simulation saves

A look inside the increasingly well-equipped virtual toolbox for composite design, analysis, and manufacturing.

Read More