Design/Simulation

The steadily growing list of IACMI resources

IACMI, the public-private composites consortium, is a little more than a year old and already has developed a strong collection of partnerships, facilities, equipment, software and material designed to help accelerate new technology development for the composites industry.

Read MoreTrace: A simple, must-have tool

This recently discovered constant in laminate calculations can put designing with CFRP materials on par with designing with metals.

Read MoreTesting is inefficient: Material simulation’s advantage over the status quo

Although simulation cannot replace validation and certification testing, it can offer a path to greater testing efficiency.

Read MoreDigital twin, digital thread and composites

How the integration of machines, sensors and software is beginning to impact composites manufacturing.

WatchLocal Motors to use Siemens software for 3-D printed vehicles

The partnership combines Siemens’ PLM software technology with Local Motors’ leadership in co-created and 3-D-printed vehicles – direct digital manufacturing (DDM).

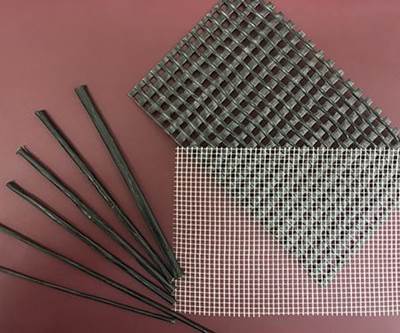

Read MoreSelective reinforcements boost “commodity” composite properties

Strategically placed advanced reinforcements reduce weight, cost while dramatically increasing mechanical performance and dimensional stability.

Read MoreCarbon fiber meets simulation in ultralight bike frame

Rolo Bikes wanted to design a bicycle frame with carbon fiber in mind, and it wanted test it in the virtual world.

Read MoreJEC World 2016, the full report

ÂÌñÏ×ÆÞ's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

Read MoreMaterials & Processes: Composites part design

Designers of composite parts can choose from a huge variety of fiber reinforcements and resin systems. That makes knowledge of how those materials work together a critically important aspect of part development. Here's a short description of what that knowledge entails.

Read More