Design/Simulation

Ducati introduces lightweight motorcycle seat support rear frame

Forged molding compound (FMC) material from Mitsubishi Chemical and Gemini Composites replaces aluminum part on Ducati Hypermotard 939, reduces part weight by 40%.

Read MoreFormula Electric Belgium's Titan race car features EconCore rPET honeycomb

Front wings and undertray comprise the honeycomb core material, the latter reducing wing weight by 26% compared to the previous year, and able to withstand forces 1,000 times its own weight.

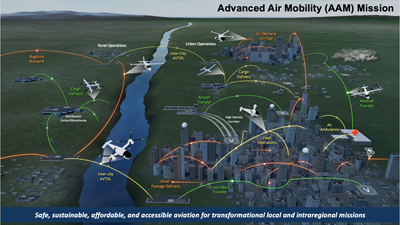

Read MoreQarbon Aerospace partners with Georgia Tech to address advanced structures in civilian vertical lift vehicles

Demonstration, testing, repair and maintenance of thermoplastic airframe structures will address technical barriers and make a business case for use of composites, metamaterials and AM for civilian air mobility.

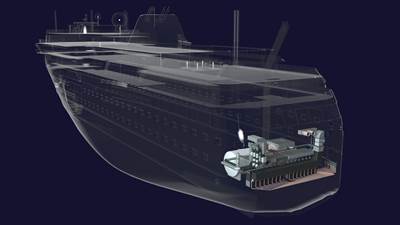

Read MoreHAV Group receives preliminary approval for hydrogen-based energy system for ships

Norwegian Maritime Authority approves LH2 tank design under the FreeCO2ast project, paving the way for commercialization of the zero-emissions marine system.

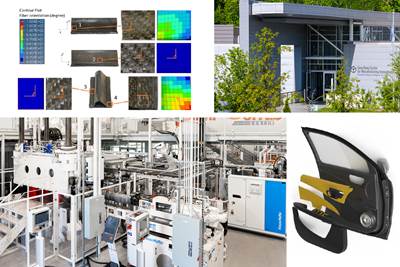

Read MoreClemson Composites Center: Working with industry to transform composites

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

Read MoreTwo-time F1 champion Fernando Alonso, SimplyEV debut Kimoa e-bike at Miami Grand Prix

The Formula One driver’s sustainable mobility Kimoa brand is debuting its fully customizable carbon fiber e-bike powered by 3D printing firm Arevo.

Read MoreSuCoHS project: Advancing composite solutions for parts with high thermal and mechanical loads

New materials, structural concepts and manufacturing using sensors for composites that resist fire, temperature and loads while providing weight and cost savings versus metals.

WatchMulti-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

Read MoreCompoTech, Bilsing carbon fiber gondola beam development key for simplifying tooling management

Stiffer EOAT design for automotive tandem press line tooling increases load capacity and productivity, overcomes strokes per minute limitation and improves factory interchangeability.

Read MoreNotox surfboards combine upcycled carbon fiber from Airbus with Sicomin bio-resin

One-hundred percent upcycled fabrics declared unusable for aerospace applications go through a wet lamination process with vacuum bag consolidation to produce the sustainable Notox R-Carbon products.

Read More