Design/Simulation

Norco to build fuselage, wings and composite components for Skyfly eVTOL aircraft

Skyfly aims to achieve a complete airframe weight of just 220 kilograms, in addition to low-cost, accurate and reliable repeatability of manufacture for series production progression.

WatchSuper Formula, Bcomp announce sustainable fiber composite bodywork

Japan’s premiere single-seater race series confirms hybrid composite parts for SF23 chassis as part of Next 50 plan.

WatchLuna Rossa Prada Pirelli adopts Siemens Xcelerator portfolio for America’s Cup composite yacht

Critical digital tools and services increase design complexity, improve manufacturing repeatability and accelerate development for composite racing yacht construction, in and out of season.

Read MoreMikrosam, H2Storage collaborate on 300+-liter Type IV hydrogen tanks

Automated filament winding cell achieving wind speeds of 6 meters/second improves production performance, shortens curing cycle for serial production of 700-bar Type IV tanks.

Read MoreThermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

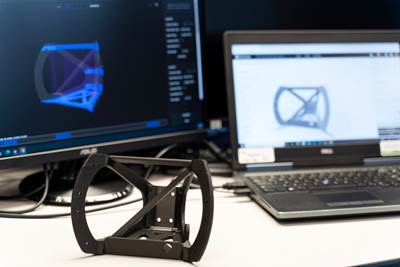

WatchMarkforged Simulation software features virtual testing capability

Virtual testing validates the strength of advanced composite parts and automatically optimizes print parameters to help lower cost and speed production.

Read MoreRe-Wind Network publishes second edition of repurposed wind blade design catalog

The fall/autumn 2022 Design Catalog presents designs and details of structures and products made from end-of-life repurposed wind turbine blades, with a new section on marine structures.

Read MoreGrand Largue Composites, Sicomin enable flax fiber-built Class40 racing yacht

Fibers, fabrics, epoxy resins and adhesives from Sicomin helped realize the lightweight, strong and stiff Crosscall yacht, capable of tackling extreme ocean racing conditions.

Read MoreFerrari unveils 2023 Le Mans 499P Hypercar

The car manufacturer’s first World Endurance Championship in 50 years, the four-wheel drive prototype combines innovation with tradition, featuring composites, a hybrid engine and an aerodynamic design.

Read MoreAnisoprint R&D team begins 3D printing center at Jacobs University Bremen

Established research environment to comprehensively upgrade CFC technology, explore new composites methods, formulations and designs.

Read More