HAV Group receives preliminary approval for hydrogen-based energy system for ships

Norwegian Maritime Authority approves LH2 tank design under the FreeCO2ast project, paving the way for commercialization of the zero-emissions marine system.

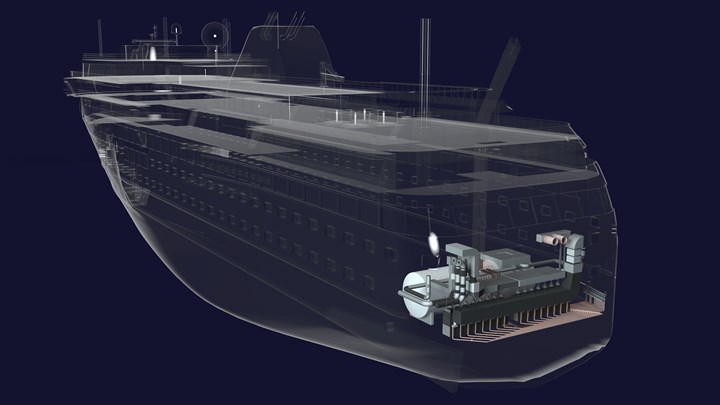

HAV hydrogen-based marine system rendering. Photo Credit: HAV Group ASA

(Fosnavaag, Norway) is said to be one of the first companies to be granted preliminary approval by the Norwegian Maritime Authority for the hydrogen-based energy system developed in the FreeCO2ast project. The approval is reported to be a major step towards the commercial use of hydrogen fuel by a commercial vessel.

“Hydrogen can be the key to achieve zero-emission shipping. This regulatory approval takes us an important step towards commercializing our hydrogen solutions and realizing the zero-emission ambition,” Kristian Osnes, project manager for the FreeCO2ast Project and managing director at HAV Hydrogen, says. “The learnings from this comprehensive approval process are highly important for HAV Hydrogen’s competence in designing hydrogen system solutions.”

According to the issued statement, HAV Group’s alternative design — comprising a liquid hydrogen (LH2) tank below decks — is considered feasible and sound in accordance with IMO guidelines on alternative design (MSC.1/Circ.1455) and is ready to advance into the final design phase.

“We are now in a position where we can offer shipowners the necessary competence in selecting hydrogen system solutions and guide them through their approval processes, as well as delivering the marine zero-emission systems. The key is to align the right technology for the right need at the right time,” Osnes adds.

HAV Hydrogen’s energy system is a spin-off from the FreeCo2ast project, which is currently developing a high-capacity hydrogen energy system that can be retrofitted onboard one of Havila Kystruten’s coastal cruise ships.

The FreeCo2ast project is supported by the Norwegian Research Council, Innovation Norway (Oslo, Norway) and Enova (Norway). Major project partners include Havila Kystruten and HAV Group’s subsidiaries HAV Design, Norwegian Electric Systems and HAV Hydrogen, in addition to the research institutions Sintef Ocean (Trondheim, Norway) and Prototech (Hordaland, Norway). Fuel cell manufacturer Powercell AB (Sweden) and tank system supplier Linde Engineering GmbH (Pullach im Isartal, Germany) have contributed with knowledge and expertise in their respective areas.

“The almost four years of cooperation with internal and external project partners in the FreeCo2ast project is a major contributor towards the preliminary design approval,” Gunnar Larsen, CEO of HAV Group ASA, adds. “The ability to cooperate closely with highly experienced sister companies covering both ship design, electrical integration and hydrogen systems, gives us a competitive edge as a group.”

Implications for composites

Though the use of composites is not specified, long-time Type IV composite pressure vessel manufacturer Hexagon Composites (Alesund, Norway), and its zero-emission spin-off Hexagon Purus Maritime (Alesund), estimates a 630% increase in tank revenues from 2025 to 2030.

“We are now seeing that the maritime requests and activities for hydrogen are rising quickly,” explains Jørn Helge Dahl, sales and marketing director at Hexagon Purus. “Hexagon Purus Maritime will develop onboard storage systems, from the shipside fuel line feeding into the storage and from the storage down to the fuel cell. We think composites are the ideal storage solution for maritime applications, due to the harsh environment, including corrosion.” For more details, see “The potential for hydrogen to fuel composites growth, part 1.”

CW also wrote about the SpaceTech4Sea project, where project coordinator Ocean Finance (Athens, Greece) worked with Cimarron Composites (Huntsville, Ala., U.S.) to develop a composite tank for cryogenic liquid natural gas (LNG) storage at -196°C that is certified for the marine market by the American Bureau of Shipping (ABS, Houston, Texas, U.S.). This tank will provide weight savings of more than 85% versus a conventional metal tank, according to the project partners, who have also completed a trade study looking at the technical and economic factors of using liquid versus gaseous hydrogen for marine vessels (see “CFRP pressure vessels for hydrogen”). Note that Cimarron Composites was acquired by Hanwha Solutions (Seoul, South Korea) in December 2020. The latter announced in 2021 that it will invest $130 million in a new production facility for Type IV pressure vessels in Opelika, Ala., U.S., part of its strategy to become a global leader in high-pressure tanks by 2030.

Related Content

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCarbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.

Read MoreNCC leads composites manufacturing phase of eXtra wing demonstrator

Key structural elements for a 6-meter section of the Airbus biomimetic wing were undertaken by NCC engineering specialists to produce 28 one-off flying parts.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More