Automation

Kineco Kaman Composites India procures 14-axis robotic C-scan cell from Fill Austria

First of its kind in India, dual robot system augments capability of this Gold Supplier, joint venture of Kineco Ltd. and U.S.-based Kaman Aerospace, to win new aerospace, defense and space contracts.

Read MoreRUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Read MoreTU/e leads project for “Smart Circular Bridge” made of biocomposites

The Netherlands-based 15-meter bridge for pedestrians and cyclists incorporates flax fibers reinforced by bioresin with glass fiber optic sensors to assist in ongoing research.

Read MoreUniversity of Nottingham commissions resin metering system for short fiber compression molding

Slack & Parr’s precision external gear pumps enable the university’s EPSRC Future Composites Manufacturing Research Hub to precisely determine the fiber-to-resin ratio for their robot-mounted liquid resin spray system.

Read MoreAirborne introduces Automated Ply Placement technology at JEC World 2022

Automated, accurate and fully integrated preforming process maximizes design freedom of composite laminates, expands material options.

WatchNatilus expands to San Diego’s Brown Field for autonomous aircraft manufacture

Natilus 12,000-square-foot facility includes hangar, runway and engineering for final assembly and testing for family of composites-intensive autonomous cargo aircraft.

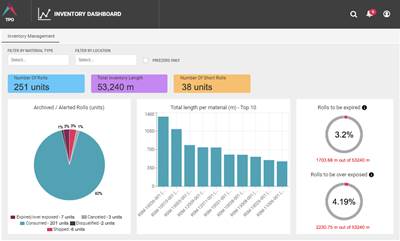

Read MoreComposites supply chain and production disruptions – how can AI and digitalization help?

Digitizing and creating the factory of the future is a journey, but it has the potential to help composites manufacturers address real-life disruptions and enable fast replanning of production operations for increased flexibility and enterprise-level performance.

Read MoreCycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MoreSaint-Gobain, Roctool join efforts to boost composite 3D textile preform parts manufacturing

3D automated knitted preform layup technology and heat and cooling technologies for additional curing efficiency open a new window of application opportunities for composite and thermoplastic parts.

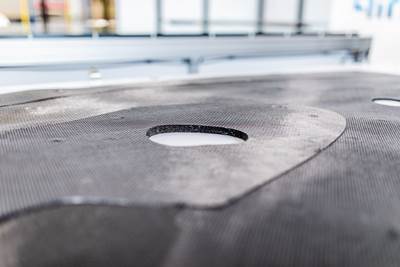

Read MoreCevotec commissions advanced SAMBA Pro Prepreg system with six-axis robots to Leonardo

A system first with two six-axis robots for tool manipulation and patch placement, increasing the capabilities to process larger, more complex part geometries for composite aerostructure applications.

Read More