TU/e leads project for “Smart Circular Bridge” made of biocomposites

The Netherlands-based 15-meter bridge for pedestrians and cyclists incorporates flax fibers reinforced by bioresin with glass fiber optic sensors to assist in ongoing research.

Share

Almer Bridge. Photo Credit, all images: Smart Circular Bridge

The -led (TU/e, Netherlands) EU project “Smart Circular Bridge” has recognized the potential of natural fiber by building three city bridges made from a biocomposite material consisting of flax and a bioresin for their light and highly stable properties. The first city bridge is now in place in Almere.

“Biocomposites hold enormous potential for a bio-based circular economy, especially since flax, unlike wood for example, is a fast-growing plant,” Rijk Blok of the Department of Built Environment at TU/e says. “They also offer an opportunity for the construction industry, which has a large CO2 footprint and high consumption of resources, both of which need to be addressed.”

In Oct. 2016, students from Netherlands-based TU/e, , and the Eindhoven’s vocational colleges built their using flax on the TU/e campus. Fast-forward to 2022, where the Smart Circular Bridge is leading the natural materials to the next level through “the intensive cooperation between science, industry and communities,” according to Blok. The “Smart Circular Bridge” consortium consists of 15 partners led by TU/e. The project team consists of five universities, seven innovative companies and three municipalities (more info on this below).

Almere bridge sensor locations and sensor readings in the (May 8-9, 2022).

The pedestrian bridge in Almere is 15 meters in length and can easily carry the weight of 275 people at once. Apart from the use of 100% natural flax fibers, university researchers note that the resin used to hold the fibers together will also come from non-fossil sources. The total amount of resin used is 25% for the first bridge in Almere, which will reach 60% or higher for follow-up bridges, achieved by using waste products from bio-diesel production and recycled PET bottles.

“The construction of the bridge in Almere make us optimistic: We expect to build bridges with significantly larger spans and higher loads in the future," Patrick Teuffel from TU Eindhoven, the lead partner in the international Smart Circular Bridge consortium, notes.

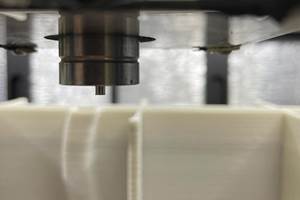

Flax fibers used to develop the biocomposite bridge.

To assist in ongoing biocomposite research, almost 100 were also used to provide data on the bridge materials’ behavior in everyday use. These sensors in particular are able to measure material strains, while acceleration sensors detect even the finest vibrations caused by wind as part of a structural health monitoring (SHM) system. Sensor data is then evaluated using artificial intelligence (AI) to search for patterns in material behavior, so engineers can refine their material models for the next bridges, as well as for other applications such as columns, façade elements, and even rotor blades for wind turbines.

“The sensors will allow us to monitor the performance of the material in specific situations,” Blok says. “For example, how does the bridge behave when 200 people walk across it at the same time? Or what happens during different seasons of the year and different weather conditions?”

Moreover, with the circular economy in mind, the project is exploring the best options when it comes to disposing of the bridge materials once they have reached the end of their lifetime after many decades of use.

The-15 meter bridge can easily carry the weight of 275 people.

“We are looking at three ways of recycling materials: mechanical (shredding parts and reuse them in new products), chemical (using pyrolysis to break down larger molecules into smaller molecules) and biological recycling with fungi,” Teuffel says. “It is important that the materials service life lasts as long as possible.To achieve this, the end-of-life options are taken into account right from the start of project.”

Project “Smart Circular Bridge” is said to be about much more than bridge construction. Rather, its researchers believe it is an example of how innovations for climate protection and circular economy can be successfully initiated. And in the case of bridges alone, it is worth considering alternative materials, as tens of thousands of bridges have to be replaced in Europe over the coming years.

The first bridge set up at the Floriade international horticulture exhibition in Almere, Netherlands, was officially opened on April 22, 2022. Two more “Smart Circular bridges” for pedestrians and cyclists will be built in Ulm, Germany, and Bergen op Zoom, Netherlands, later in 2022 and in 2023 respectively.

Related Content

JEC World 2025 highlights: Trends in aerospace, new space and defense

CW editor-in-chief Scott Francis discusses trends in aerospace on display at JEC World — as the composites industry awaits a new single aisle aircraft program, the industry puts continued focus on new space, defense, UAM.

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreRead Next

Refurbishing bridges at half the time, cost versus replacement

Instead of demolishing and rebuilding bridges, SUREbridge doubles the strength and durability of existing structures with an FRP deck for a smart, sustainable solution.

Read MoreIn-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More