Automation

Virtek/Plataine: Integrating laser projection systems with AI-based cloud software

Sean Francoz, Director of Product Management at ViRTEK and Avner Ben-Bassat, President & CEO of Plataine discuss their partnership centered around automated laser projection solutions and AI-based cloud software. Their partnership hopes to improve on-time delivery as well as quality control for aerospace manufacturers.

WatchNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

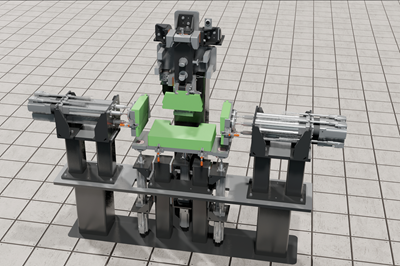

WatchFast-FlexMont2 project targets optimized, large-structure CFRP assembly

Advanced measuring and referencing methods, highly precise positioning technologies and continuous digital process control by Fraunhofer IFAM demonstrate automated rudder hinge assembly.

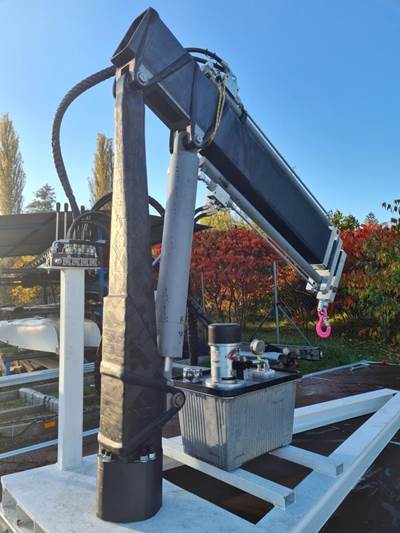

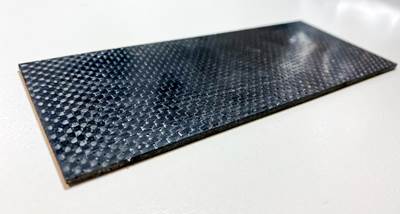

WatchCompoTech, RTI collaborate on composite mast, telescopic boom for mobile cranes, davits

Cost-competitive carbon fiber-reinforced epoxy crane design uses CompoTech’s automated composites processes, eliminating welding or heat treatment and producing 50-70% stiffer structures.

Read MoreBroetje-Automation works with Boeing Germany, consortium in “Shimless Assembly” project

Foundation for future aircraft programs aims for -75% manufacturing time, -25% cost via end-to-end digitization, tolerance compensation and force-controlled joining.

Read MoreSiemens Gamesa, Airborne collaborate on automation of wind turbine blades

Joint efforts combine years of expertise in the manufacture of wind turbine blades, composite processing and automation to scale up operations.

Read MoreWisk unveils sixth-generation self-flying eVTOL

The carbon fiber four-seater’s autonomous flight with human oversight and simplified design sets out to meet and exceed rigorous commercial safety standards.

Read MoreEHang progresses with type certification of autonomous EH216-S eVTOL aircraft

EHang enters a more in-depth review phase for the EH216-S with the CAAC’s approval of the Project Specific Certification Plan.

Read MoreSwinburne, Sparc Technologies researchers to create graphene-enabled smart composites

Connected smart structures are being built that can be wirelessly monitored in real time for hard-to-detect defects, enabling safer, more reliable and cheaper air and space travel.

Read MoreVelocity Composites launches digital manufacturing cell to improve material efficiency

Industry 4.0 manufacturing cell is tailored to effectively and efficiently trace individual composite plies through the entire value stream.

Read More