Automation

Autoneum future-proofs GFRTP production with Evoris digitalization platform

Extensive plant modernization includes new automation and digitalization solutions procured from Dieffenbacher.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

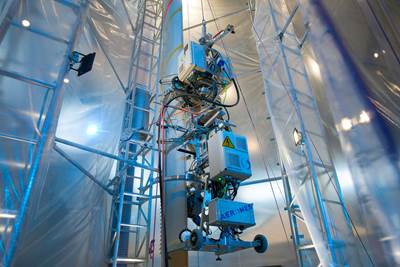

WatchAerones unveils modular robot for Level 1-3 wind turbine maintenance, repair

Resilient, full-service system can perform a variety of tasks five times faster and more safely than human technicians, while proactively addressing extreme erosion progression.

Read MoreSiemens, Deloitte demonstrate Industry 4.0 innovation at The Smart Factory @ Wichita

New dedicated space enables companies to experience the future of smart manufacturing and the power of digitalization using the Siemens Xcelerator portfolio.

Read MoreBabyark launches smart, composites-intensive car seat

Impact-absorbing car seat approaches safety holistically with carbon fiber and D3O materials and embedded sensors for real-time monitoring.

Read MoreNatilus partners with Janicki for blended wing autonomous aircraft

The Tier 1 supplier will design, fabricate and provide quality assurance of primary composite structures for the Natilus N3.8T prototype, to be used for air freight transport.

Read MoreNew Vestas business provides automated blade leading edge maintenance solution

BladeRobots is a standalone business developing a wireless, automated robot that can reportedly provide maintenance up to four times faster than traditional methods.

Read MoreEastman Machine automated cutting equipment increases HanseYacht efficiencies by 85%

Since implementation of its first conveyorized cutting system, the recreational boatbuilder regularly seeks ways to improve its composite material handling processes.

Read MoreITA graduate develops AI-supported monitoring system to detect damaged carbon fiber

Deniz Sinan Yesilyurt wins a Young Talent Award from VDMA for his Bachelor’s thesis that used machine learning to recognize various fiber defects with up to 99% accuracy during thermal stabilization.

Read MoreLoop Technology becomes a member of AMRC

The industrial automation technology specialist joins as a Tier 2 member at the AMRC to pursue advanced automation projects that will further cultivate U.K. productivity.

Read More