Search Results

Showing 171 – 180 of 702 resultsSpanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

The research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber.

The automated, modular system enables clean, safe and speedy production for all aircraft component sealing.

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

It was a big year for new products in the composites industry. Take a look at ÂÌñÏ×ÆÞ’s top 10 most popular product pieces based on Google Analytics and check out what you might have missed.

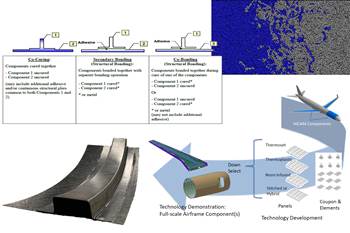

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Hybrid core material is simple to process, highly economical and exhibits a shear modulus up to four times greater in comparison to PVC and PET.

The funded project aims to further develop SwiftComp modeling software to better predict the durability of composite flexbeams on Navy rotorcraft.

New stretch-breaking concept consistently produces carbon fiber that is eight times more formable with strength equivalent to continuous fibers, enhancing its prospects to form to complex aircraft shapes and cut manufacturing costs.