Broetje-Automation presents automated sealer for aircraft components.

The automated, modular system enables clean, safe and speedy production for all aircraft component sealing.

Source | Broetje-Automation

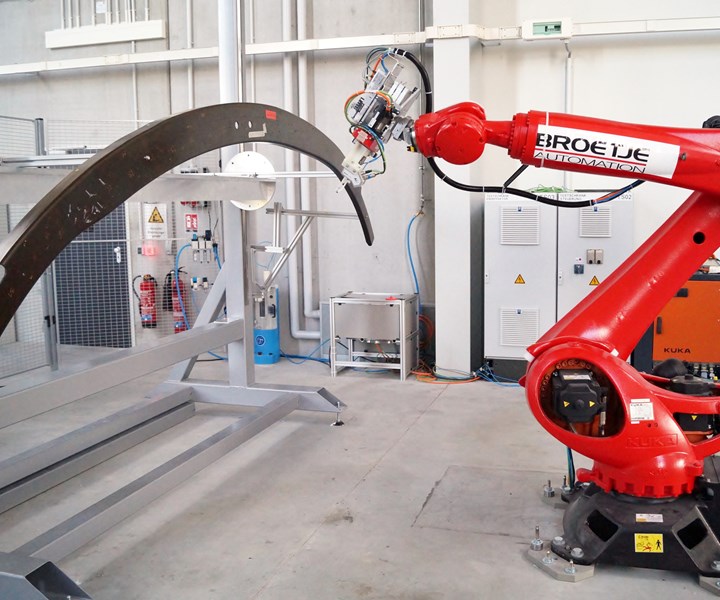

Supplier and distributor of automated systems for aircraft construction, Broetje Automation (Rastede, Germany) presents its automated solution for sealing aircraft components. Meant to replace the time-consuming process of manually sealing edges of aircraft parts, the company claims the product’s modular system will enable faster production by carrying out sealing applications safely and cleanly, and with high precision and effectiveness, even on complex components. Broetje-Automation claims the concept saves up to 20% in overall efficiency, while improving the quality of the components simultaneously.

An application with collaborating robots (CoBots) is also possible. Source | Broetje-Automation

Broetje-Automation gave the sealer a modular structure to meet the complexity of aircraft components, including processing components at precise locations to avoid contamination; cleanly sealing hard-to-access, curved surfaces and joints; and mixing difficult-to-process sealants for the aircraft components themselves. Depending on the application, the system can be operated autonomously within a robotic cell or with small, collaborative robots ("CoBots"). The system also provides a "digital twin," which is integrated into the automated NC programming environment "SOUL OLPS" and can fully simulate the processes. The system, the company states, is thus optimally prepared for use in future digital factories.

Further, to meet global customer requirements, the technology team at Broetje-Automation has developed various end-effectors for the application of the material. The system can use polysulfite and epoxy

sealants, both using pre-mixed cartridges and with a "mixing-on-the-fly" module that can mix several components live during sealing.

Four types of sealing — with individually developed special nozzles— are currently available: Fillet sealing (e.g. for clips, stringers, frames), cap sealing, (for sealing of rivet heads), epoxy edge sealing (for composite components) and complex shapes (curves, connections).

Related Content

-

Laser cleaning in composites manufacturing

Laser cleaning technologies for cleaning production molds for composites offer alternatives to harsher, less-friendly methods with features like automation and higher power cleaning.

-

TAVieDA project team cuts aircraft door production time using thermoplastic composites, welding

Fraunhofer groups, Trelleborg and Airbus develop modular, fully automated assembly system concept to replace metals and time-consuming assembly that shows potential for scalability.

-

JEC World 2025 highlights: Trends in aerospace, new space and defense

CW editor-in-chief Scott Francis discusses trends in aerospace on display at JEC World — as the composites industry awaits a new single aisle aircraft program, the industry puts continued focus on new space, defense, UAM.