CAMX 2021 exhibit preview: MF Tech

France-based MF Tech meets aerospace, automotive, sports and industrial application needs with its robotic filament winding solutions.

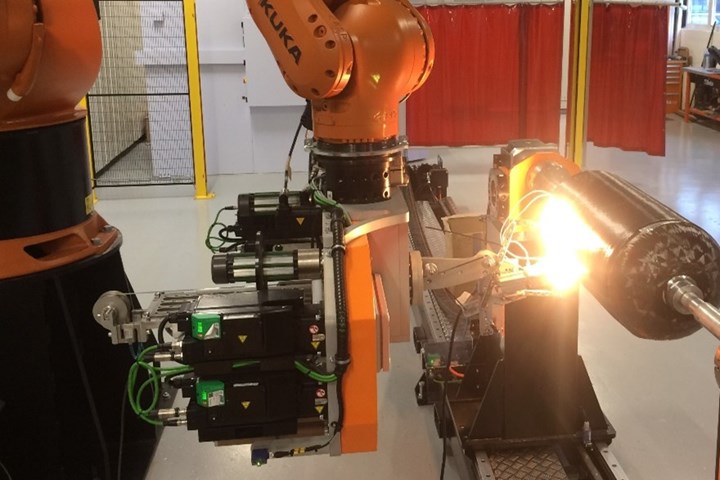

Photo Credit: MF Tech

Since its start in 2004, (Argentan, France) has seen growth in the request for serial and individual robotic filament winding solutions for aerospace, automotive, sports and industrial applications. For several years, MF Tech says it has also positioned itself in the hydrogen market.

Further, the company’s growing sales and service network is based on branches and sales agencies located in China, Germany, Japan, Russia, South Korea and the U.S. Since 2018, MF Tech has belonged to the Coriolis Group (Lorient, France).

MF Tech offers four different processes to meet a customer’s production or R&D needs. Further, the company says its filament winding robots have several competitive advantages over a conventional filament winder including being faster and more compact; retaining a high degree of automation; easy programming; 4.0 connected; and MTBF up to 99%.

Related Content

-

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

-

Post Cure: Parallel winding technique demonstrates CFRP anisogrid design optimization

Over the years, CIRA has demonstrated its patented CFRP parallel winding technique in a variety of ways for space applications. The lattice structure for the Vega-C launcher stage is a prime example.

-

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.