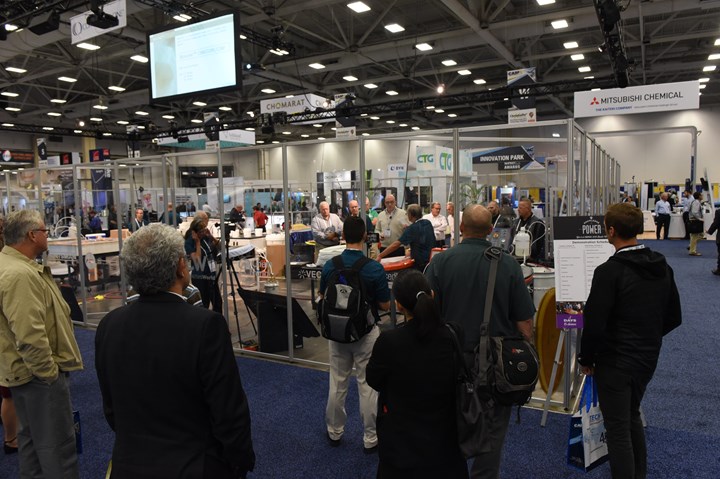

On the show floor at CAMX 2018. Photo Credit: CW

When the coronavirus pandemic struck in early 2020, it was tempting to imagine a best-case scenario in which vaccines were developed quickly, produced quickly, distributed quickly and widely taken, leading to an orderly return to life as it was. A realistic person, however, could more easily imagine what we got: fast vaccine development and distribution, but a cultural and political environment — in the U.S. and other places — that would produce a chaotic, uneven and disjointed return to a normalish life, hindered by various levels of political dysfunction, mistrust of science and medicine, widespread disinformation and the emergence of more virulent strains of the virus.

Given the uncertainty created by this discombobulated recovery, it’s difficult for us, from a business and industry perspective, to clearly demarcate the point at which we can and should resume many of the activities — customer visits, in-person trade shows, in-person conferences — that are part and parcel with our professional lives. During the summer, at the peak of the vaccine rollout in the U.S., it certainly felt like we were entering the beginning of the end of the pandemic. Today, however, with the delta variant ascending, we are all experiencing a certain amount of déjà vu all over again.

Still, at some point, each of us (and our employers) must decide for ourselves when we feel safe enough and comfortable enough to re-enter the in-person work world. For me, that point was Aug. 26, when I traveled to Post Falls, Idaho, U.S., for a tour of thermoplastic composites manufacturing specialist ATC Manufacturing. It was my first plant visit since Feb. 29, 2020, when I toured Spirit AeroSystems’ A320 spoiler production line in Prestwick, Scotland. That’s 544 days between in-person visits.

For the broader composites industry, the return of the in-person experience arrives this month in the form of the 2021 trade show and conference, which will be held Oct. 19-21 in Dallas, Texas, U.S. Ironically, but not surprisingly, the last major in-person composites industry trade event was the 2019 CAMX show and conference, held in late September of that year in Anaheim, Calif., U.S. That’s 754 days from the end of the last CAMX to the start of the next. (What would you have said if I told you, in Anaheim in 2019, that we would not meet as an industry again for 754 days?)

To be sure, the return of CAMX in person will, understandably, lack the scale and crowds of the 2019 version. Indeed, the number of exhibitors and attendees will almost certainly be less than historical averages, but that doesn’t matter. The symbolism of this in-person milestone event is arguably more important for an industry and people who are eager to reconnect on a personal and professional level. It’s like that long-awaited family reunion that, although missing a few cousins, uncles or aunts, offers a welcome chance for those who do make it to catch up, get acquainted and reacquainted.

The symbolism of CAMX notwithstanding, there is something else that can and will drive interest in the show. Although the composites industry has lacked in-person interaction for 754 days, there has been during that time absolutely no lack of research, innovation or product development throughout the composites industry supply chain — from software and raw materials to intermediates and finished parts. And all of that innovation is in dire need of exhibition.

CW polled CAMX exhibitors and asked for information on new products and technologies that will be featured at the show. We were flooded with responses, some of which you can find in this issue in our CAMX preview on p. 22. We published others in the . And you can find all of the previews we’ve received to date on the CW site here.

Finally, for further proof of the high level of innovation at work in the composites industry, be sure to check out the nominees for the CAMX Awards and the Awards in Composites Excellence (ACE). The material and process technologies on display in these submissions are as impressive as I have seen in the history of the show.

The bottom line is this: Wherever we are in the evolution of the pandemic, there remain myriad compelling reasons to attend CAMX in Dallas. The entire CW staff will be there and we look forward to connecting with you there. Safe travels.

Related Content

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreTPC, FRP poles and fire-retardant panels

CAMX 2025: Avient Corp. is bringing its latest composites innovations including Polystrand, GridCore and Hammerhead solutions.

Read MoreMaximize your experience: CAMX 2025 exhibit previews, Part 1

This list of 90+ exhibitor previews solicited by CW offers a glimpse into the various technologies, emerging trends and solutions attendees should look for on the CAMX show floor.

Read MoreNew brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More