ATC Manufacturing

1224 N Lean St.

Post Falls, ID 83854 US

509-893-4100

sales@atcmanufacturing.com

About ATC Manufacturing

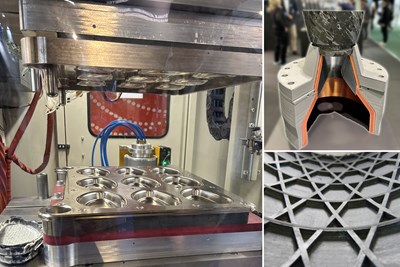

Manufacturer of thermoplastic composite aircraft structures and assemblies. Specializing in fabrication of parts with thermoplastic UD tapes and fabrics. Core technologies include continuous compression molding and stamp forming. Perform all part finishing operations in-house. AS9100 and NADCAP approved.

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

ATC Manufacturing Supplies the Following Products

- Adhesive Bonding

- Aerospace, Aircraft Interior

- Aerospace, Flight Control Surfaces

- Aerospace, Fuselage/Wing

- Automated Tape Laying

- Coating & Painting

- Compression Molding

- Continuous Laminating

- Cutting, Finishing, & Machining

- Laminate Sheets, Solid

- Other Composite Structures

- Other Thermoplastics Fabricating Services

- Pressure Forming

- Profiles

- Prototyping

- Surface Treatment

- Tubes

- Welding & Sealing

Editorial, News, and Products

-

Troubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

-

The AAMMC Tech Hub: Ramping U.S. production of large thermoplastic composite aerostructures

CW talks with Syensqo, Spirit AeroSystems and other consortia members about current funding, specification of the next world’s largest press, organizational structure and projects to support U.S. companies in the race to deliver >40,000 sustainable and efficient aircraft over the next 20 years.

-

A legacy of innovation in advanced thermoplastic composites

ATC Manufacturing, a 2024 Top Shops honoree, enables high-rate aerospace production with sustainable, lightweight and durable thermoplastic composite solutions.

-

ÂÌñÏ×ÆÞ reveals 2024 Top Shops benchmarking survey results

CW recognizes the qualifying composites fabricators in its 2024 Top Shops program and highlights some of the survey's general findings.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

AAMMC chosen as top 20 Regional Technology Hubs

Chosen from nearly 400 applicants nationwide, the 47-member Inland Northwest consortium in Spokane-Coeur d’Alene prepares for Phase 2 in an effort to produce a testbed facility for high-rate composites manufacturing R&D.

-

Inland Northwest consortium files application for aerospace composites center

Nearly 50 aerospace leaders and research universities have filed an application with the EDA for federal designation and Phase 1 funding to create a composite aerostructures Tech Hub, the American Aerospace Materials Manufacturing Center.

-

ATC Manufacturing selected for NASA's HiCAM project

ATC will provide expertise in thermoplastic composites manufacturing to NASA’s Hi-Rate Composite Aircraft Manufacturing (HiCAM) project.

-

NASA awardees to develop sustainable aviation composite tech

Fourteen Advanced Composites Consortium organizations support the evaluation and development of next-gen thermosets, resin-infused composites and thermoplastics at small scales.

-

CW presents "CW Tech Days: Thermoplastics for large structures"

Attend this May 18th interactive webinar sponsored by Altair, Mitsubishi Chemical Group, Toray and Collins Aerospace which will explore the materials and processing technologies that are enabling the transition into thermoplastics.

-

ATC Manufacturing, Boeing expand long-term thermoplastic composites agreement

With this contract expansion, the Post Falls-based composites manufacturer now supplies parts for all active Boeing commercial aircraft programs.

-

Inside Teijin’s thermoplastic tape expansion

Teijin is qualifying its second thermoplastic tape line in Heinsberg, Germany, that will significantly expand the company’s presence in this material segment.

-

SAMPE North America seeks active volunteers for technical committees

The global professional member society encourages SAMPE members and non-members who are interested in actively engaging, sharing expertise and networking to develop advanced technological solutions.

-

Plant tour: ATC Manufacturing, Post Falls, Idaho, U.S.

ATC is at the top of the list when it comes to thermoplastic composites and aerostructures manufacturing. CW explains why.

-

With CAMX, the composites industry takes a step back toward normal

The symbolism of CAMX is important for an industry and its members who are eager to reconnect on a personal and professional level.

-

2020 CW Top Shops recognizes top-performing facilities

CW's second annual Top Shops benchmarking survey helps composites fabricators put their operations into perspective and illuminates top-ranking facilities.

-

Revolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

-

RAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

-

CW's top 10 articles of 2019

It’s time to reflect upon the trends and innovations seen in the composites industry over the past year and contemplate what might be ahead in 2020.

-

Accelerating thermoplastic composites in aerospace

ATC Manufacturing produces millions of thermoplastic composite parts per year, and is investing for future growth.

-

Thermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

-

DARPA presents TFF program for low-cost composites for defense

Results reviewed at SAMPE 2019 show new materials and side-by-side comparisons of thermoset, thermoplastic, HP-RTM and press-forming, including PtFS molding cell.

-

Tooling technologies positioned for speed, control

Tooling is one of the most rapidly evolving segments of the composites industry, as new technologies and processes like 3D printing, OOA infusion, thermoplastic composites reshape how molds are made.