DARPA presents TFF program for low-cost composites for defense

Results reviewed at SAMPE 2019 show new materials and side-by-side comparisons of thermoset, thermoplastic, HP-RTM and press-forming, including PtFS molding cell.

The Defense Advanced Research Projects Agency (DARPA, Arlington, Va., U.S.), part of the U.S. Department of Defense (DoD), has a long history in advancing the development of composites technology. This includes programs such as Affordable Composites for Propulsion, Out of Autoclave Materials — which led to the widespread use of the 5320-1 family of prepregs in the defense industry — and most recently the TRUST program for bonded composite primary structures.

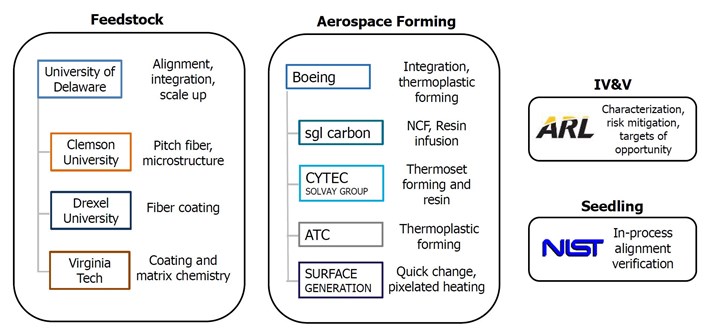

Overview of TFF program. SOURCE | “Advances in Composite Materials and Design Tools” by Jan Vandenbrande, program manager, Defense Sciences Office (DSO), DARPA at SAMPE 2019 (May 20-23, Charlotte, N.C., U.S.)

Launched in 2015, DARPA’s Tailorable Feedstock and Forming (TFF) program is aimed at enabling the rapid, low-cost and agile manufacture of composite parts weighing less than 20 pounds. Composite parts trade very well against metallics for large, stiffened-skin parts with processes such as automated fiber placement and tape layup. However, on a typical tactical military aircraft, about 80% of the parts that make up the entire airframe structure weigh less than 20 pounds. The vast majority of these parts are made from metals because composites can only win in trade studies for defense parts >20 pounds.

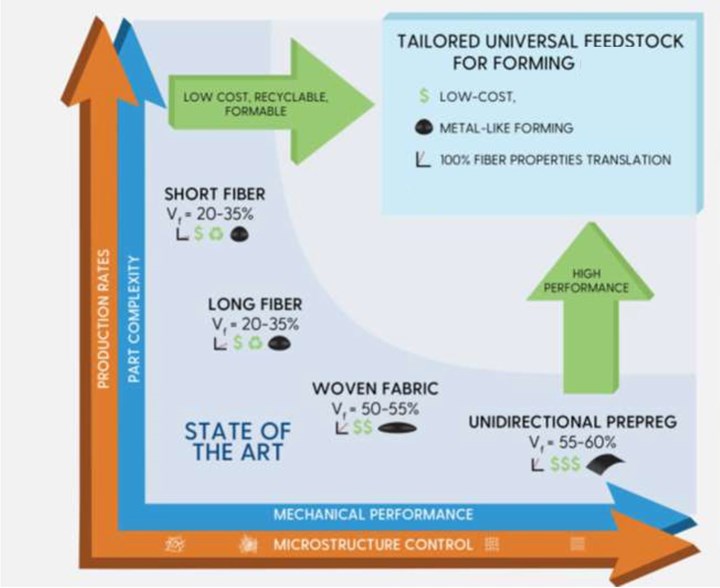

To address this, TFF is developing a tailorable universal feedstock for forming (TuFF) — a material using traditional PAN based carbon fiber cut to specific lengths (ultimately the program hopes to use pitch carbon fiber) and highly aligned discontinuous fibers that can be tailored in length, surface modification, matrix and hybridization with other materials while achieving sheet metal-like formability via rapid processes such as stamping. The TuFF subprogram is led by the University of Delaware (UD, Newark, De., U.S.).

Target performance for Tailored universal Feedstock for Forming (TuFF) material. SOURCE | “Advances in Composite Materials and Design Tools” by Jan Vandenbrande, SAMPE 2019.

Forming and molding process comparison

TuFF’s parallel for manufacturing is the forming subprogram, led by The Boeing Co. (Chicago, Ill., U.S.) and referred to as RApid high-Performance Molding (RAPM). Partners in RAPM span not only companies well-known in aerospace, including materials supplier Solvay (Alpharetta, Ga., U.S.) — Solvay Composite Materials (Brussels, Belgium and Tempe, Az., U.S.) — and thermoplastic composite structures specialist ATC Manufacturing (Post Falls, Id., U.S.), but also companies more often associated with automotive and industrial markets like SGL Carbon (Wiesbaden, Germany) and pixellated temperature control specialist Surface Generation (Oakham, Rutland, U.K.), which has delivered automated molding systems for compression-molded laptop computers, injection-molded plastics and a range of composites parts and processes.

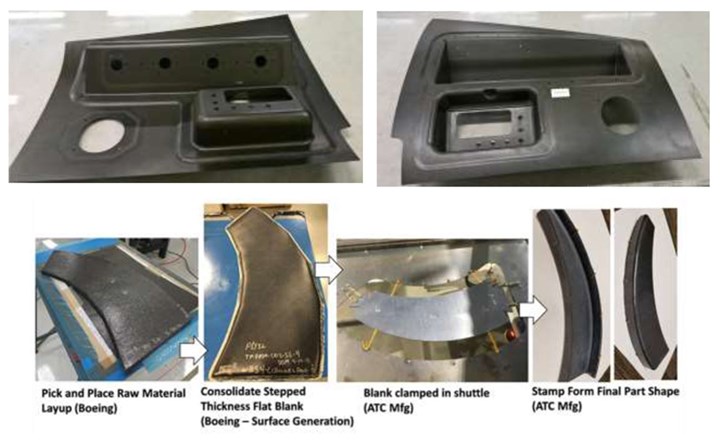

RAPM compares multiple forming methods on a series of demonstrator parts. SOURCE |“Advances in Composite Materials and Design Tools” by Jan Vandenbrande, SAMPE 2019.

Results presented at SAMPE 2019

Both TuFF and RAPM presented results at SAMPE 2019 — 14 presentations in total — including material properties testing of new materials and forming demonstrations for a set of challenging demonstrator parts. The latter has enabled side-by-side comparisons of materials and processes, including thermoplastic composite stamp-forming and thermoset resin transfer molding (RTM), including development from automotive-like high-pressure RTM (HP-RTM) to a lower-pressure variant similar to the Ultra RTM process used by Audi and Voith Composites. Processes have also been developed using a spring-loaded frame for holding 2D reinforcements to prevent wrinkles and other defects during preforming/molding of 3D shapes. The cycle time benchmark for all processes was less than 30 minutes on tool. Some parts made with thermoplastic composite stamping achieved cycle times as low as 5 minutes.

Selection of SAMPE 2019 TFF Presentations

- Formability of TUFF Composite Blanks —Shridhar Yarlagadda, University of Delaware Center for Composite Materials (UD-CCM)

- Closed Loop Recycling of CFRP Into Highly Aligned High Performance Short Fiber Composites —Dirk Heider, UD-CCM

- Fiber Alignment Evaluation Through X-Ray Computed Tomography — Jennifer Sietins, U.S. Army Research Laboratory

- Rapid High-Performance Molding (RAPM) for Small Parts — Gail Hahn, The Boeing Company

- Fabrication of a Complex Part with Deep-Draw Sections by Resin Transfer Molding — Tom Tsotsis, The Boeing Company

- Spring Frame Press Fabrication of Aerospace Production Components — Timothy Luchini, The Boeing Company

- Rapid High-Performance Molding of Structural Thermoplastic Composite Parts — Gail Hahn, The Boeing Company

- Agile Analysis of Manufacturing Cell Costs for Molding of Small Composite Parts — Daniel Charles, The Boeing Company

Surface Generation automated molding cell

RAPM also evaluated Surface Generation’s patented PtFS system across a range of near-net and net-shape aerospace thermoset and thermoplastic composite processing applications. The cell processes prepreg, organosheet and dry fiber, the latter used in resin infusion.

Interim findings were detailed in ‘Development of Scalable Dynamic Control Architectures for Flexible Composites Manufacturing Work Cells’ by Steven Shewchuk, The Boeing Company.

Surface Generation supplied the RAPM team with a fully integrated bespoke PtFS clamping, tooling and molding cell capable of producing composite components up to 0.9 meter by 0.9 meter. The cell can be reconfigured to produce different parts in minutes and has been tested with multiple configurations including vacuum, resin infusion, press-clave thermoset and thermoplastic composite consolidation. It has a wide-ranging and significant history of part processing data as well as the ability to mix isothermal and cyclic processing.

Related Content

Composite Integration presents webinar on liquid resin infusion

On July 30, 2025, company experts will discuss the role of LRI in delivering scalable, OOA composite production for the aerospace sector.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreSyensqo, Teijin Carbon achieve aerospace qualification for composite resin

Resin infusion system Prism EP2400 achieves NCAMP qualification with Teijin Carbon’s advanced NCF and UD reinforcements.

Read MoreInduction heating system enables OOA composites processing

JEC World 2025: Roctool focuses attendees’ attention on the light induction tooling (LIT) system targeting efficiency, sustainability and performance.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More