Automated preforming: Intelligent automation in pick-and-place systems

Layups go industrial with hand-like grippers that can fold fabric or prepreg into corners and robot-mounted cameras that inspect from fabric to cut plies to fiber gaps in final preforms.

This is #6 in my series on Automated Preforming. The first five can be found here:

- Automated Preforming: The numbers and landscape

- Automated Preforming: Glide Forming

- Automated Preforming: Quilted Stratum Process (QSP)

- Automated drapability testing

- Automated Preforming: Drapability simulation and a Holistic Quality Optimization

There is also a print article on automated preforming, split into two parts:

This blog comes from my discussions with Composite Alliance Corp. (CAC, Dallas, TX, US). I interviewed CAC for the two-part print article above, but was not able to include most of the information due to lack of space. So I”m finally sharing it here.

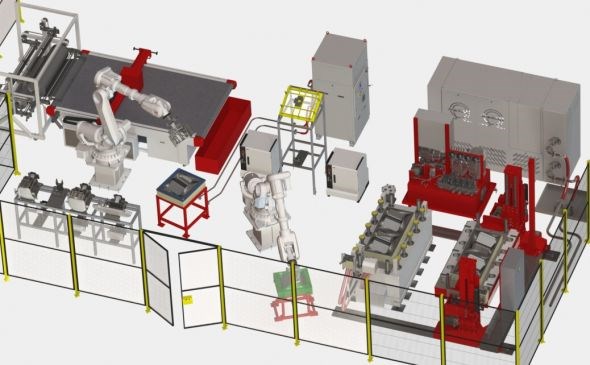

CAC and Techni-Modul Engineering work with partners to design, test and install automated composites production lines, as well as individual components and smaller fabrication cells.

The line shown here was developed in collaboration with Israel Aerospace Industires (IAI, Tel Aviv, Israel). ​SOURCE: CAC and Techni-Modul Engineering.

CAC provides turnkey automated production lines for composites, but also single components, including systems for injection and dispensing, preforming and handling, as well as presses and tooling.

CAC draws from decades of experience from four major partners:

- Techni-Modul Engineering – turnkey systems, automation

- Isojet Equipments – injection and dispensing systems

- – reinforcements including 3D preforms and also resin research

- – electroformed nickel and composites tooling

“We are not tied to a specific technology,” says CAC sales director Marc-Ruddy Thimon, “so we can work with any technique the customer is interested in.” He notes that compared to many other players in preform technology, “our approach is more general, based on the wide scope of skills we have. We can include several technologies, but our decision is based on what the parts require.”

Thimon says CAC and Techni-Modul Engineering (TME) can supply automation based on prepreg, dry fiber, unidirectional (UD) tape or woven fabrics, with the main target being aerospace but it also supplies systems into automotive. “However,” he acknowledges, “these markets are quite different, and thus, the solutions are as well.”

CAC won the 2016 ACE award at CAMX (Sep 26-29, Anaheim, CA, US) in the Manufacturing Equipment and Tooling category for "Innovative Robotized Preform Cell Providing 3D Stacking and Control".

This ACE award-winning automated cell produces 3D preforms for aerospace I-beams using specially developed grippers and software. The robot lifts the first of two formed C-sections (photo on left) which are placed and compacted to form an I-beam (far left of photo on right).

SOURCE: Composite Alliance Corp. and Techni-Modul Engineering

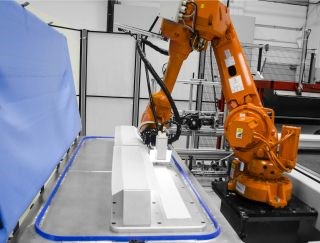

“We combine pick and place robots with preforming and quality inspection,” Thimon continues. “We develop many of our end effectors in-house and this is one of our areas of strength.” He describes CAC’s development of specialized end effectors that operate like hands, allowing 2D materials to be folded into complex shapes made using resin transfer molding (RTM).

The automated systems that CAC develops start from unrolling the fabric. “We can work with existing equipment at the customer or we can provide a complete cell,” Thimon explains. “We then look at the cutting system required and communication with the cutting station automation. If it’s prepreg, we can integrate removing the backing film during unrolling.” He notes that CAC is receiving more requests for prepreg now and there are many ways to remove the backing film, both before or after cutting.

The next station is automated layup, using one or more pick and place robots and laying into the preforming tool. “We also include debulking for prepreg or compaction for bindered dry fabric, where we apply heat and pressure,” Thimon adds. “Next, there is contour cutting/trimming for molding of net shape parts. And finally, insertion into a curing tool and molding, followed by demolding.” He points out that all transfers are automated depending on the type of part and process requirements. Some systems use all robotics, while others use a combination of robotics and automated static machinery.

|

|

Robotic 3D contour cutting after vacuum compaction of a preform (left) and

“Intelligent Automation” camera inspection system using specially-developed software.

SOURCE: Composite Alliance Corp. and Techni-Modul Engineering

Big Data and “Intelligent Automation”

“We integrate control for all parts of the process and connect to a central control unit,” Thimon explains, “so the operator has all of the data, such as temperatures and pressures, all controlled from a central system.” He claims this “Intelligent Automation” is one of the main features of CAC and TME systems.

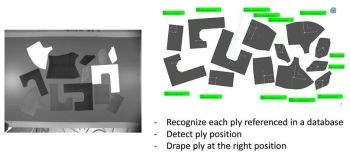

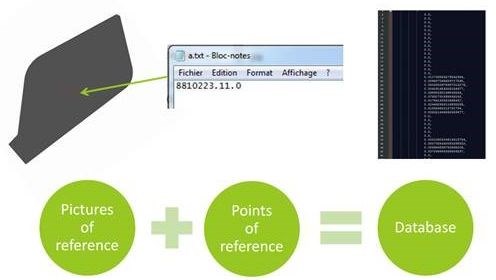

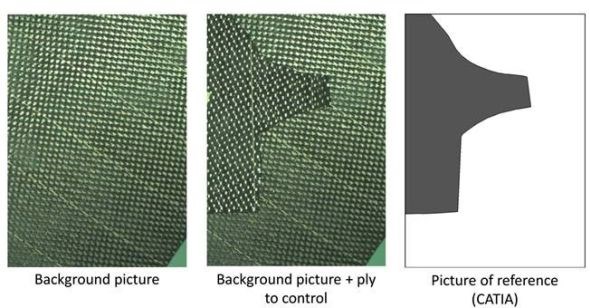

“We integrate a camera into either the robotic arms or stationary equipment for continuous vision inspection throughout preforming operations,” says Thimon. “When you unroll the material, it will check the fiber orientations. On the cutting table, one of our newer features is that the system can recognize each cut ply in a reference database. It uses the camera vision system to register and compare the shape and fiber orientation, but also looks at its sequence from the cutting program and data from the digital part design file. This is useful for minimizing errors in direct work flows from cutting table to tool and also for preforming with stored kits of cut plies.”

|

|

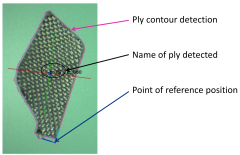

CAC and TME automated preforming cells feature “Intelligent Automation” which integrates inspection via camera vision systems that can detect and track each ply in a reference database using pictures, points of reference and marked labels

to ensure proper layup and positioning on the preforming tool.

SOURCE: Composite Alliance Corp. and Techni-Modul Engineering

For working with kits, Thimon says the system will track the pieces per kit to ensure proper layup and also detect the end of a ply for new ply placement. “This system too is integrated into central control, so it logs each step as part of the whole assembly,” he adds. “The system puts a reference around the entire preform and the edges of the tool to ensure proper positioning of the preform on the preforming and curing tools. However, it also compares the contour of each ply vs. the preform to inspect fine positioning during pick and place layup.” It also detects proper placement of cuts and darts in 2D preform plies as well as unacceptable gaps between fibers after ply placement.

SOURCE: Composite Alliance Corp. and Techni-Modul Engineering

Another important use is to detect foreign object and debris (FOD) at different points in the preforming process. Even the best automation can still be susceptible to human introduction of error. This is why another new feature has been developed to compare points of reference in the production cell. The system basically performs a type of calibration at the beginning of a production cycle — or on demand, for example, to troubleshoot a detected ply placement error — to make sure that different pieces of equipment and other targets, such as a preforming tool with a hole or cutout, are all aligned properly. “The goal of these latest features is to add more flexibility and ways to work in these automated cells.”

CAC is currently working with 3-4 major aerospace OEMs and well-known Tier 1 suppliers to develop automated composite preforming and molding cells/production lines. Most of these will use prepreg. More details on CAC and TME “Intelligent Automation” systems will be presented by Thimon and project engineering director Stephane Besson at the conference Nov. 28-30 (Charleston, SC, US).

Related Content

From the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MoreBallistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More